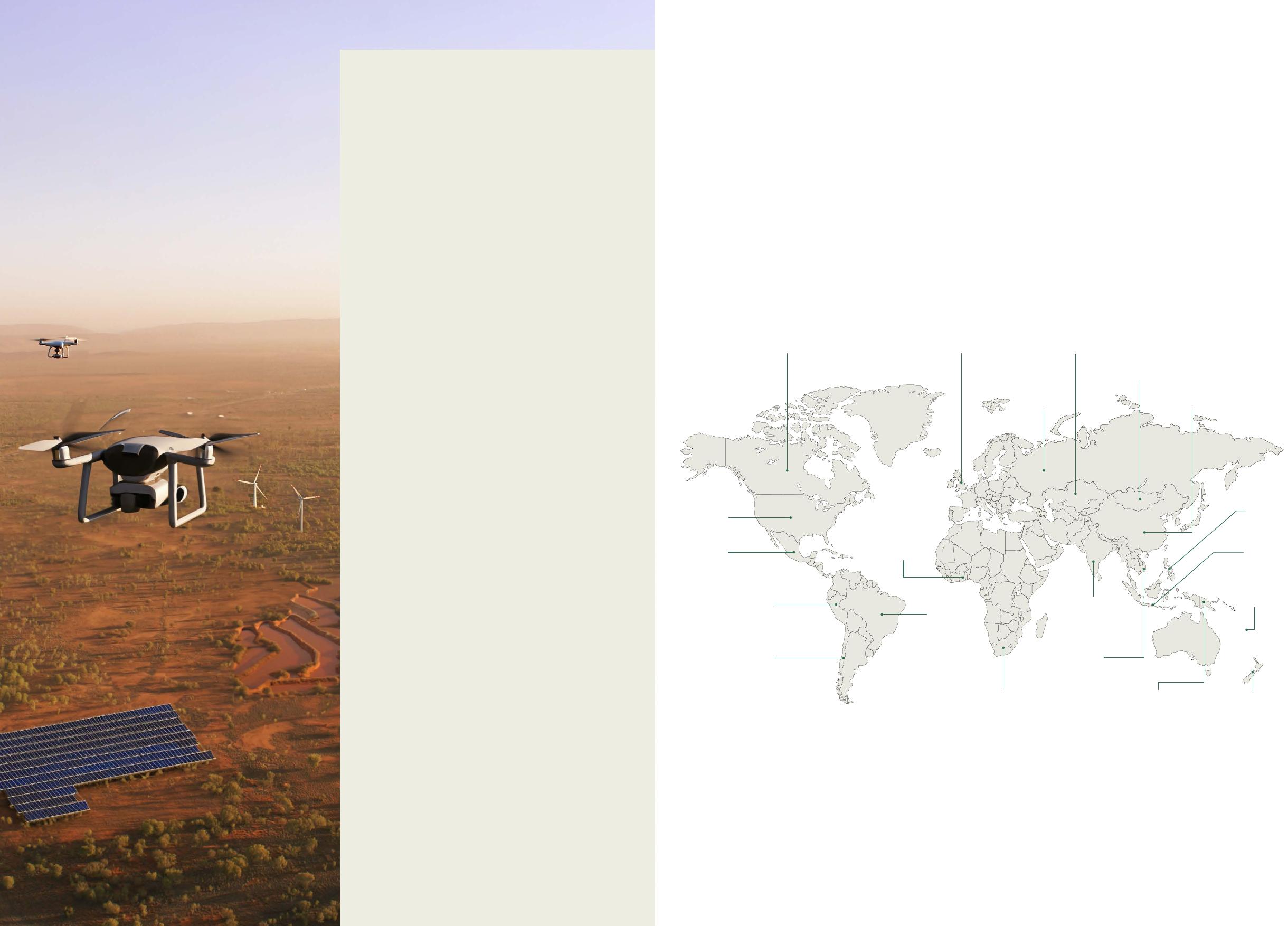

AcceleratingSustainableMiningAustralianMiningEquipment,TechnologyandServices(METS)sectorContentsEmpoweringGreenAmbitionAustmineistheleadingnot-for-profitassociationSustainableMiningTechnologies�02fortheAustralianMiningEquipment,TechnologyTheAustralianTradeandInvestmentCommissionandServices(METS)sector.AustmineexiststoTheSmartWaterMine�06(Austrade)promotesAustraliaontheglobalpromotetheglobaladvancementoftechnologystage,growsanddiversifiestradeandhelpsbuildandinnovationinmining,andsupportmemberssoTheCommunityMine�12Australia’seconomicsecurityandprosperity.theycanachievegreatersuccess.Withover100officesathomeandworldwide,TheZeroCarbonMine�20AustradehelpsAustralianbusinessesachieveAustmine’smembershipreflectstheimpressivediverseexportoutcomesandwininvestmentdiversityoftheMETSsector,representingaTheSmallFootprintMine�26neededtogrow.rangeofcompaniesfrommultinationalsoftware,engineering,andmanufacturingfirms;toTheWasteFreeMine�34Austradehastheexpertise,thecontactsagilestart-ups,smallandmediumenterprisesandthemarketintelligencetohelpgrow(SMEs)andtechnologists;throughtoresearch,AustralianMETSListing�42AustralianbusinessesandbuildAustralia’seducation,governmentandprofessionalservices.economicprosperity.AustminepartnerswithminingorganisationsAustralianMiningEquipment,TechnologyandaroundtheworldtohelpthemachievetheirServices(METS)productsandservicesareknownsustainability,productivityandsafetygoalsfortheirinnovativeprocessesandoperationalthroughcreatingstrongconnectionstotheefficienciesdevelopedoverdecadesofcontinuoustechnologies,innovationsandexpertiseoftheimprovementworkingwithworldleadingresourceAustralianMETSsector.companies,andarewellestablishedinsupportingsustainabilityanddecarbonisationobjectives.ContactContactDisclaimerCopyright©CommonwealthofAustralia2023132878+61293574600ThisreporthasbeenpreparedbytheCommonwealthofThematerialinthisdocumentislicensedunderaCreativesustainable@austrade.gov.auinternational@austmine.com.auAustraliarepresentedbytheAustralianTradeandInvestmentCommonsAttribution–4.0Internationallicence,withtheaustrade.gov.auaustmine.com.auCommission(Austrade).Thereportisageneraloverviewandisexceptionof:notintendedtoprovideexhaustivecoverageofthetopic.The•theCommonwealthCoatofArmsinformationismadeavailableontheunderstandingthatthe•theAustralianTradeandInvestmentCommission’slogoCommonwealthofAustraliaisnotprovidingprofessionaladvice.•anythirdpartymaterial•anymaterialprotectedbyatrademarkWhilecarehasbeentakentoensuretheinformationinthis•anyimagesandphotographs.reportisaccurate,theCommonwealthdoesnotacceptanyMoreinformationonthisCCBYlicenceissetoutatthecreativeliabilityforanylossarisingfromrelianceontheinformation,orcommonswebsite:https://creativecommons.org/licenses/fromanyerrororomission,inthereport.by/4.0/legalcode.Anypersonrelyingonthisinformationdoessoattheirownrisk.AttributionTheCommonwealthrecommendsthepersonexercisetheirownBeforereusinganypartofthisdocument,includingskillandcare,includingobtainingprofessionaladvice,inrelationreproduction,publicdisplay,publicperformance,distribution,totheiruseoftheinformationfortheirpurposes.dissemination,communication,orimportation,youmustcomplywiththeAttributionrequirementsundertheCCBYlicence.TheCommonwealthdoesnotendorseanycompanyoractivityEnquiriesaboutthislicenceandanyuseofthisdocumentcanreferredtointhereport,anddoesnotacceptresponsibilitybesentto:advisory@austrade.gov.au.foranylossessufferedinconnectionwithanycompanyoritsactivities.UsingtheCommonwealthCoatofArmsThetermsunderwhichtheCoatofArmscanbeusedareAcknowledgementofcountrydetailedontheDepartmentofthePrimeMinisterandCabinetwebsiteatpmc.gov.au/government/commonwealth-coat-arms.InthespiritofreconciliationweacknowledgetheTraditionalPublishedOctober2023.CustodiansofcountrythroughoutAustraliaandtheirconnectionstoland,seaandcommunity.WepayourrespecttotheirelderspastandpresentandextendthatrespecttoallAboriginalandTorresStraitIslanderpeoplestoday.AcceleratingSustainableMining1SustainableFigure1.AustralianMETSExportDestinationsin2020(AustmineNationalMETSSurvey2020)MiningTechnologiesForMETScompaniesthatareengagedinexporting,thebelowfigureillustratesthekeyinternationalmarketsbypercentageofcompaniesexportingtothedestinations.WhyAustraliaCanadaUnitedKingdomKazakhstanTheminingindustryplaysacritical321919roleinsecuringasustainablefutureforourplanet.MiningprovidestheRussiaMongoliaessentialresourcesneededtocreatethe1516renewableenergytechnologies,electricvehicles,greenconstructionmaterials,Chinamedicaldevicesandspacetechnologies19thatwillguidetheworld’ssustainableeconomicandsocialdevelopmentacrossUnitedGhanaIndiaPhilippinesthenextcentury.States191837Toensuretheresponsibledeliveryofresources38BrazilVietnamIndonesiaforcurrentandfuturegenerations,miningmustMexico191837strikeabalancebetweenincreasingproductionNewofmineralsandadoptingmoresustainable14SouthAfricaPapuaNewoperationalpractices.Toreduceimpactsonthe30GuineaCaledoniaenvironmentandsecuresociallicencetooperate,Peru3615miningmustlooktonewtechnologies,processes18andbusinessmodelsinitspursuitofsustainability.NewZealandChile33Inthispursuit,AustralianMiningEquipment,32TechnologyandServices(METS)companiesarenaturalpartnersfortheglobalminingindustry.TheAustralianMETSsectorhasbeenattheforefrontofdevelopingandimplementinginnovativepracticesandcutting-edgetechnologiesforminingoperationsaroundtheworld.Drivenbyapioneeringspiritandacommitmenttoexcellence,METScompanieshavebecomerenownedforsolvingthemostdifficultindustrychallengesintheharshestglobalminingenvironments,fromlarge-scaleopen-pitcopperminesintheAtacamaDesertofChiletocomplexundergroundgoldprojectsinthesubzerotemperaturesofNorthernCanada.Itisthisentrepreneurialapproachandwillingnesspartnerships,andcollaborativerelationshipstototakeonachallengethathasledthequicklyandefficientlyrespondtocustomerneedsAustralianMETSsectortobeoneofthemostaroundtheworld.internationalisedsectorsglobally.Over65%ofAustralianMETScompaniesexport,andtheyhaveestablishedsophisticatedsupplychains,strong2AcceleratingSustainableMiningAcceleratingSustainableMining3Figure2.AustralianMETSsnapshot(AustmineNationalSurvey2020)TheharshoperatingclimateinAustraliahasTheZeroCarbonMine:focusedtheAustralianresourcesandMETSShowcasingthepracticesadoptedtomonitor,$114bnAUD300,00+industryonsustainability.Aswecollectivelystriveanalyseandreducecarbonemissionsfromminingtorisetothechallengeofclimatechange,theoperations,includingrenewablepowergeneration,TotalRevenueHighlyskilledAustralianMETSsectorhasincreasedthisfocuselectricvehiclesandenergyefficientsystems.professionalsprovidinginnovationandexpertisetosupporttheminingindustryinbecomingglobalsustainabilityTheSmallFootprintMine:9/1064%leaders.LeadingafundamentalshiftinthebusinessmodelsandoperationalpracticesofminingConsiderInvolvedinInthispublication,weshowcasesomeofthecompaniestocreatemoreprecise,adaptable,andInnovationCollaborativeinnovativesustainablesolutionsthatthelowimpactprojectsreadyforthefuture.ImportantProjectsAustralianMETSsectorhastooffer,andcompellingexamplesofwheretheirtechnologies,TheWasteFreeMine:65%26%ideasandknow-howhavebeenimplementedtoInvestigatingthecirculareconomymethodologiesovercomethemostchallengingenvironmentalandthatcanbeutilisedtotakeminewasteandExportSpecialiseinsocialissues.turnitintovaluablebuildingmaterials,energySustainabilitytechnologiesandpreciousresources.32%SolutionsWefocusonthekeyareasofsustainabilitythatareimpactingoperationsnowandintothefuture,Havecapabilitiesin37%lookingthroughthelensofwheretheindustryDigitalTechnologyisstrivingtobeifwecansuccessfullyaccelerate&AutomationConsiderTechnologysustainablepractices.aKeyOpportunityTheSmartWaterMine:Astheindustryseekstoworkcollectivelytoshapeasustainableminingindustry,welookforwardDemonstratingthesolutionsneededtoprotecttobuildingpartnershipsbetweentheAustralianourmostprecioussharedglobalresource–METSecosystemandminingcompaniesacrosswater.Rangingfromminewatermanagementtheglobe.andmonitoringthroughtowatertreatmentanddesalination.TheCommunityMine:Re-imaginingthetraditionalrelationshipsbetweenminesandcommunitiestocreatevalueforlocalstakeholders,preserveculturalartefactsandimprovethepublicperceptionofmining.4AcceleratingSustainableMiningAcceleratingSustainableMining5SustainableMining:CaseStudyTheSmartWaterMineTechnologytosafelyreleaseminewaterintosensitiveenvironmentsCustomerdescriptionAlargecoalminingcompanyoperatingnearsensitivehumanandnaturalenvironments.CompanynameProblemEvocraThesubjectsite,acoalmineoperatinginaEvocraisanAustralian-ownedwatertreatmentsensitivenaturalheritagearea,invitedEvocratocompanyofferingsolutionstoremovehazardousevaluatetheircurrentwatertreatmentprocesscontaminantsfromoftendifficult-to-manageandprovideadviceonpossiblesolutionstomeetwatersourcestoimprovethequalityofthetheirstringentwaterreleasecriteria.waterforreuseorrelease.ItssolutionshaveabroadrangeofapplicationsovermanyUndergroundminewaterwasimpactedbyheavyminingandotherheavyindustriestoresolvemetals,requiringexpensivetreatmenttoallowcomplexwatercontaminationissues,whiledischargeintonearbysensitivenaturalwaterways.providingimprovedwaterresourceeconomicsandsustainability.Likemanyminingsites,thisoperationhadhistoricallyusedatraditionalpHadjustment,Reducingwaterconsumptionandensuringqualitywaterforcommunitiesisakeyoxidationapproachwithdissolvedairflotationnecessityinmovingtowardamoresustainableminingindustry.(DAF)toremoveheavymetalsfromtheaffectedwater.Analysisshowedthatthemassofreagentadditionwasmorethan34timesthemassofthetargetmetalload.Thisdisproportionatereagentuseincreasedthemassofthewastesludgebeingproducedandrequiringsubsequentdisposalbyapproximately97%.Miningoperationsandmineralsprocessingaremonitoringandcontrolsystems,state-of-theSolutiontraditionallywater-intensive,sothereisanurgentartdesalinationprocesses,andwaterreuseandneedtoadoptnewpracticesandreduceimpactsrecyclingtechnologiesuniquetothedemandsofEvocraproposeditspatentedOzofractionativeonwatersustainability.miningoperations.CatalysedReagentAddition(OCRA)processasasolutiontomeetingthewatertreatmentAustralianMETScompanieshaveembracedKeybusinesscapabilities:requirementswhilesignificantlyreducingthethechallengesofwaterconsumptionand•Watertreatmenttechnologiesclient’soperatingcosts.conservation.Theyareattheforefrontof•Minewatermanagementdevelopingsmartsolutionsthatarereshapingthe•WaterconservationtechniquesEvocra’sinitialanalysisoftheexistingwaterlandscapeofresponsiblemining,andforginga•Waterqualitymonitoring&controltreatmentprocessindicatedthatthreeofthepathtowardamoreefficient,eco-conscious,and•Waterreuseandrecyclingreagentsusedintheprocessweresuperfluous,water-resilientindustry.•Desalinationprocessesprovidingnobenefittotheprocess,withimmediatecostsavingstobegainedfromAustralianMETScompanieshaveexpertiseintheirremoval.watertreatmenttechnologies,innovativeminewatermanagementpractices,waterconservationmethodologies,advancedwaterquality6AcceleratingSustainableMiningAcceleratingSustainableMining7Evocraconductedaseriesoftrialsonrawwaterremoved89.6%ofcopper,88.6%ofcadmiumCaseStudyoriginatingfromtheminesiteutilisingtheand72%ofironpresentinthewater.CopperOCRAprocesswhichdemonstratedthattheandcadmiumwereremovedtobelowlaboratorySolidsremovaltosavewaterandincreasepumplifetechnologyeffectivelyremovedmetalsfromdetectionlimits.affectedminewaters,meetingthesite’sstringentCompanynameThesystemdesignedbytheOLEOLOGYResearchdischargerequirements.WhiletherearearangeofreagentsthatcanbeOLEOLOGYandEngineeringDepartmentfeatures2setsappliedtoheavymetalcontaminationsviatheof2regenerablemediavesselsinparallel,withResultsOCRAprocess,EvocracontinuedtheuseoflimeOLEOLOGYprovidesengineeredwaterautomaticbackwashingbasedonscheduledtoallowdirectoperationaleconomicassessment.treatmentsolutionstotheminingindustry,variableparameters.AnintegralfilterpressalsoResultsofthetrialsprovedthattheOCRAResultsshowedthatthereplacementoftheincludingadvancedoilywaterseparators,PFASreducesthewastetoasolidthatthecustomerprocesseffectivelyremovedthetargetmetalsofclients’traditionalprocesswiththeOCRA(PerfluoroalkylandPolyfluoroalkylSubstances)caneasilydisposeof.concern–cobalt,zinc,nickel&manganese–belowprocesswouldleadtoareductionoflimeusagebyremovaltonon-detect,andwaterrecycling/theregulatoryauthority’senforcedlimits,allowinggreaterthan80%,anda69%reductioninsludgereuse.Forthepast21yearsOLEOLOGYhasledTheclientwasabletoavoidchemicaldosingand,dischargetothelocalsensitiveenvironment.production,providingsignificantcostreductionswatertechnologyinnovationwithnewandrobustwithonlyamediafiltration,thesolutionwasinreagentprocurementandwastemanagement.technologiesfitforcommonandchallengingsimple,robustandautomated.TheclientwillalsoTheOCRAprocessreducedtheconcentrationsapplications.havesignificantlyreducedannualoperationaloftheprioritycontaminantsby99.9%forContactexpensesasthemediawilllastupto8years.cobalt,99.4%forzinc,98.9%fornickelandwww.evocra.com.auCustomerdescription78.1%formanganese.Inadditiontomeetingthesolutions@evocra.com.auAmultinationaltier-oneundergroundgoldminingResultsprioritypollutantcriteriatheOCRAprocessalsocompanywithmultiplesiteoperationslocatedinWesternAustralia.AsevidentfromthePhase2results,thenewsystemdischargeswaterbelowtheclient’srequirementsforsolidscontent.ThesolidsremovedbytherobustsolutiondesignedbyOLEOLOGYensurethatthewatercanbeusedforundergroundactivities,andtheclient’spumpsoperatemoreefficiently,savingtheirbottomline.Phase2–StagedFiltrationResultsbelow.ProblemTheclientislocatedinadry,remoteareawithfinitewaterresources,andtheywererunningoutofwatersupplyoptions.OLEOLOGYwasengagedtodesignarobustsolutiontorecyclewaterforuseintheirundergroundminingoperations.Theywereseekingtoremovesolidsfromthewatersotheirpumpswouldnotsufferfromthesealsprematurelyfailing.8AcceleratingSustainableMiningSolutionContactwww.oleology.com.auTheclientcontractedOLEOLOGYtoundertakesales@oleology.com.auadetailedPhase1(Raw)&andPhase2(Treated)testandtrialprogram.ThetestandtrialstageAcceleratingSustainableMining9includedpassingtheclient’swaterfromsitethroughascaled-downsystemtoprovetheefficiencyofthestageofthefiltrationprocess.AustralianMETSCapabilitiesWatertreatmentTheSmartWaterMinetechnologiesMinewaterBeyondLOMmanagementCDSWaterconservationClean&RecovertechniquesConceptEnvironmentalServicesWaterqualityEMMConsultingmonitoring&controlEnvirosuiteOperationsWaterreuse&EvocrarecyclingHydroAustraliaDesalinationLiquidIntegritySystemsprocessesMagnumAustraliaOLEOLOGYAcceleratingSustainableMining11PhibionSedgmanWorldpoly10AcceleratingSustainableMiningSustainableMining:CaseStudyTheCommunityMineHelpingminersimprovesociallicencetooperatespreadsheetsanddisparatesystemstomanagethisresultinginchallengeswithdataconsistency,integrity,sharingandgovernance.AsustainableandgreenermineisnotsolelydefinedbyitsoperationalefficiencyCompanynameSolutionandreducedenvironmentalimpact,butalsobythepositivelegacyitleavesontheK2flycommunityinwhichitoperates.K2fly’sLandManagementsolutionsspanacrossK2flyisatechnologyproviderofenterprise-accesstoland,culturalheritagemanagementtoAustraliapossessesadeepappreciationforAustralianMETScompanieshavedevelopedlevelResourceGovernancesolutionstoassetgrounddisturbancepermittingandapprovals.Indigenouscultures,facilitatedbyitsdiverseproductsandservicestoweavesocialandethicalintensiveandextractiveindustries.TheirThisprovidedtheclientwithaneffective,heritage.Thisculturalsensitivityiscomplementedconsiderationsintominingprocesses,recognisingsolutionsdrivetowards‘netpositiveimpact’transparentprocesstohelpensureobligationsarebyarobustregulatorylandscapethatprioritisestheintegralrelationshipbetweenmininginESGcompliance,disclosure,andtechnicalunderstood,risksmitigated,andstrongresourcecommunityengagement,environmentalintegrity,operationsandthewell-beingofstakeholders.assurance,throughplatform-basedSaaSgovernanceremainedevidentforallstakeholders.andsocialresponsibility.cloudsolutions.ItallowedtheclienttocentralisestakeholderKeybusinesscapabilities:communications,interactionsandgrievances,Communityengagementisintertwinedwithissues•StakeholderengagementexpertiseK2fly’sNaturalResourceGovernancesuitecreateintegratedworkflowsandvisualisetheofsocialimpactassessment,Indigenousand•CulturalheritagepreservationintegratesdataforLandAccess,Culturalinformationrequiredtosupportlandaccesslocalcommunityrelations,diversityandinclusion,•SocialimpactassessmentHeritageManagement,Communityengagement,acrosstenements,infrastructureandapprovals.andmineclosureplanningandimplementation.•Indigenous&localcommunityrelationsandGroundDisturbancepermittingintoEngagingwiththecommunityensuresthat•Labourrelationsoneenterpriselevelknowledgebase.ThisResultsprojectbenefitsareequitablydistributed,and•Diversity&Inclusionprovidesthefoundationforriskmanagement,potentialnegativeimpactsaremitigated.A•Mineclosureplanning&implementationstakeholderinclusion,transparency,andTheresultsobtainedwereinasingularplatformholisticviewofsustainabilityincludesnotjustgovernancethatminingcompaniescanbeproudtomaintainsociallicencetooperatebytheimmediateenvironmentalconcernsbutof.K2fly’ssolutionisspatiallyintegratedandaddressingthemultifacetedchallengesoflandalsothewell-beingofthepeopleaffectedbyprovidesthedataintegrityrequiredtomaintainmanagement,accessagreements,conductingminingactivities.andimproveonacompany’ssociallicenceassessmentsandgainingapprovals.Inaddition,tooperate.theplatformprovidedcertaintyintheprocessofmanagingacquisition/relinquishmentandCustomerdescriptionannualexpendituredisclosures.ItalsoallowedtheclienttoreduceriskthroughgovernanceofAnironoreminerinAustraliaandtheAmericas.keydataanddecisions.Theywereabletoapply,approve,track,reportandsubmitclosureoftheirProblemgrounddisturbancepermitsandrehabilitationcommitmentsallthroughonedatabase.TheprocessofobtainingaccessandapprovalstolandisextremelycomplexascompaniesneedContacttoadheretoESGrequirementsandoutcomes.www.k2fly.comTheclientwastryingtonavigatethroughthisinfo@k2fly.comlandscapebyengagingstakeholderstomanageriskbutfounditdifficulttomonitorandtrackprogress.Theywereusinginternaldatabases,12AcceleratingSustainableMiningAcceleratingSustainableMining13CaseStudyResultsothersitesandexplorationoperationsacrossAustraliaaspartoftheirstandardheat-stressMonitoringhydrationforahealthyworkcommunityInlate2019,Newcrestconductedapilottrialofmanagementpractices.EachyearNewcresttheMX3HTSatTelferandfoundthesystemtoconductsapproximately100,000MX3hydrationbeaneasytouseandeffectivealternativetoassessmentstoensureworkersarehydratedandtheirexistingurine-basedhydrationassessmentreadyforwork.approaches.ContactFollowingthispilot,Newcrestconductedawww.mx3diagnostics.comsite-widerolloutoftheMX3HTSattheTelfersupport@mx3diagnostics.commineandmadetheuseoftheHTSmandatoryworkforcetoregularlyself-monitorhydrationforallon-sitecontractors.Newcresthaslevels,minimisedisruptiontoregulartasks,andnowintroducedthetechnologyatarangeofprovideclearactionableguidancetoallowworkersCompanynametotakecorrectiveactionandavoidheat-relatedMX3Diagnosticsinjuries.MX3DiagnosticsisahealthtechnologycompanySolutionthatspecialisesinnon-invasivepoint-of-carediagnostics.MX3’scustomersincludemining,ToaddressNewcrest’shydrationmanagementconstruction,pro-sports,emergencyservices,needs,MX3introducedtheMX3HydrationTestingandmilitarygroupswhousetheiruniquesaliva-System(HTS).basedhydrationassessmenttechnologytoenhancetheirperformanceandsafeguardTheMX3HTSisahandheldsystemthatassessesagainstadverseevents.hydrationbydeterminingSalivaryOsmolaritywithdisposableteststripsthatcollectsalivadirectlyCustomerdescriptionfromthetongue.UsingsalivatomonitorandtrackhydrationstatusviatheMX3HTSisaquick,NewcrestMiningisAustralia’sleadinggoldminingconvenient,non-invasive,andaccuratewaytocompany,withoperationsinAustralia,PapuaNewassesshydrationstatusofworkers.GuineaandCanada.Newcrest’sTelferMineintheEastPilbararegionofWesternAustraliaisoneofHydrationassessmentswiththeMX3HTSareAustralia’slargestgoldandcoppermines,withcompletedinseconds–minimisingdisruptiontobothopen-pitandundergroundoperations.workflows,andhelpingworkersprepare,perform,andrecoverwhenworkinginextremeconditions.ProblemMX3hydrationassessmentsareautomaticallyHydrationisakeyfactorinfluencingtheresilienceloggedthroughtheMX3AppandPortal,allowingofworkerstoheatstrainandheatrelatedinjuries.organisationstoeasilygenerateinsightsintoInappropriatelymanaged,heatstresscanplaceworkforcehydrationanddemonstratecompliancesignificantphysicalstrainonworkers,leadingtowithheatstressmanagementprocedures.seriousandchronichealthissues,anddramaticallyreducingproductivity.Directmeasurementofhydrationisanessentialcomponentofheat-managementontheminesite.NewcrestMiningwantedtoidentifyhydrationassessmenttechnologieswhichcouldimprovesafetyattheirTelfermines.PriortoengagingwithMX3,Newcrestreliedonurine-basedhydrationassessmentapproaches,whichwereimprecise,inconvenientandinvasive.Newcrestwaslookingforanalternativesolutionwhichcouldallowtheir14AcceleratingSustainableMiningAcceleratingSustainableMining15CaseStudy“WithinaweekofgettingtheseresultsIwasoncallswithourseniormanagers...thatkindofphoneQuantifyingcommunityengagementthroughdatacallhasneverhappenedformeunlesstherewasanissueatoneofthesites;unlesstherewasaprotest;[Thesociallicencemeasure]takesitoutoftheunlesstherewasaroadblock;unlesstherewasrealmofanecdotalqualitativedata,andtakesitsomesortofsignificantissue...Andwecanhavetheintotherealmofscience...andwe’resurroundedconversationbeforeasituationgetsbad...thistoolbyengineersandfinancepeoplewholiveondata.”isliketheearlywarningsystemtosay‘somethingAaronSteeghs,YamanaGoldisnotrighthere,let’sfixit’.”AaronSteeghs,YamanaGoldContactwww.voconiq.cominfo@voconiq.comCompanynameSolutionVoconiqIndesigningthecompany’snewsociallicenceVoconiqisadatascienceandengagementmeasure(basedonVoconiqLocalVoicesdata),companythatworkswithindustrytoassistYamanaGoldstaffaskedthemselves–whatdoesinbuildingstrongerandmoreproductivethegeneralmanagerofaminesitereallyneedtorelationshipswithcommunity.Itssolutionsareknowaboutthecommunity,andwhatdoesthegroundedinengagementscienceandincludeCEOandtheBoardreallywanttoknow?Thosesmartcommunitysurveys,proprietaryanalyticsprinciplesfedthroughintotwokeyfeaturesoftheandflexiblereporting.newmeasure.CustomerdescriptionThefirstfeatureistoensurethatitproducesactionable,strategicdata–toknowwhat’sYamanaGoldisamid-sizedmultinationalmininghappeningontheground;whatpeoplethinkaboutcompanyoperatinginCanada,Brazil,Argentinathecompany;andhowitcanbeimproved.TheandChile.In2015thecompanyadoptedanewsecondfeatureistoensurethatthatdatahasapproachtomeasuringhealthandsafety,directvisibilitywithinthecompany–thatitgoesenvironmentalandsocialrisksacrossthetositegeneralmanagers,seniorexecutivesandcompany.Aspartofthatapproach,YamanaGoldboardmembers.hasbeenworkingwithVoconiqtodeveloptheirsociallicenceindicesacrossalloperationalsites.ResultsProblemThecompanyidentifiedasignificantdipinthetrustscoresatoneoftheirsites(‘Operation3’),YamanaGoldhadfounditdifficulttomeasure,andwhilethescoreswerestillabovethe‘riskcommunicateandaddresssociallicenceissueszone’,itimmediatelyledtoactionwithinthewithintheorganisationbecauseofalackofcompany.Withinaweekofthoseresultscomingsystematicmeasurement.Havingregularandintothecompanytheyhadbeencommunicatedstructuredsite-by-sitemeasurementsoftothesitegeneralmanagerandcommunitytrustandacceptance,aswellasthefactorsrelationsteams;toseniorfunctionalmanagersunderpinningthem,changedthat.atheadquarters.Throughtheseinformedconversations,andbydiggingdeeperintothe“Inafast-pacedenvironmentsuchasmining,itLocalVoicesdata,thecompanywasabletogetacanbechallengingtogettheattentionofthebettersenseofwhatwasgoingonandwhatkindmanagementteamandtofacilitateaction,whenofactionstheywouldneedtotaketoaddressthewedon’thavedatatobackupthenarrative.dropincommunitytrust.16AcceleratingSustainableMiningAcceleratingSustainableMining17userid:532115,docid:150311,date:2024-01-02,sgpjbg.comAustralianMETSCapabilitiesStakeholderTheCommunityMineengagementexpertiseBiTQCulturalheritageCarbonNeutralpreservationEarthTechnologySocialimpactEMMConsultingassessmentEnvirosuiteOperationsIndigenous&localGeoMobycommunityrelationsK2flyLabourrelationsMX3DiagnosticsDiversity&inclusionParvateESGMineclosureplanningPX4Software&implementationSentientComputingSpaceDraftAcceleratingSustainableMining19Voconiq18AcceleratingSustainableMiningSustainableMining:CaseStudyTheZeroCarbonMineBatterysystemstosupportundergroundminevehicleelectrificationMininghasanimportantroletoplayincombatingclimatechange,andadoptingzeroCompanynameforminersafetyandlong-termhealthwhilstcarbonpracticesisakeypartofreducingoperationalemissions,andtheimpactsmining3METechnologyconcurrentlymakingminingmoreefficientforhasontheenvironmentenvironmentalandproductivityreasons.3METechnologydeliverscleanenergyBeyondenvironmentalbenefits,azerocarbonAustralianMETScompaniesplayapivotalroletechnologytomining,developinganddeployingThecustomerwasseekingtoconvertbothapproachenhancesoperationalresiliencebyinaidingminingcompaniestoattaintheirzeropowerful,zero-emissionbatteryelectricsystemsexistingandnewundergroundvehiclesandreducingdependenceonfossilfuelsandaligningcarbongoals.Theyofferabroadrangeofforminingvehiclesandequipment.Itspecialisesloadersfromdieseltoelectric.withevolvingregulatoryandmarketexpectations,solutionsacrossareassuchascarboncaptureandincustomdesigningandmanufacturingsafe,ensuringlong-termviabilityandcompetitiveness.storage,energystoragesystems,cleanenergyenergy-denselithium-ionbatteryanddriveSolutionsolutions,seamlessintegrationofrenewablesystemsthatpowerminingandheavy-dutyTheAustralianminingindustryhastakenaenergyintoexistinggrids,meticulousenergyequipment.3METechnology’scurrentand3METechnologydesignedacustomisedfullsignificantsteptowardssustainabilitybyefficiencymeasures,determinedelectrificationfuturecapabilitiesspanbatterysystems,batteryelectricintegratedsystemutilisingtheirembracingambitiouszero-carbontargets,andefforts,pioneeringhydrogenfueltechnologies,systemsintegration,remotecyber-secureassetin-house,proprietaryengineeringcapability.AustralianMETScompaniesplayasubstantialandinnovativerenewableenergyapplicationsmonitoring,andin-fieldsupport,providingThesolutionincludedbatterydesign,remoteroleinprovidingtechnologiesandservicestotailoredspecificallyforminingoperationsatrueend-to-endsolutionforoff-highwaybatteryandassetmonitoringsystem,fullassistminingcompaniestoachievethesegoals.electrification.Theyprioritiseelectrificationofsystemintegration,factoryandsitetestingAustralia’sdistinctivechallenges,stemmingKeybusinesscapabilities:undergroundminingequipment.andongoingsupportusing3METechnology’sfromitsvastgeographicalexpanse,relianceon•Carboncaptureandstorageproprietaryproducts:fossilfuels,anddedicationtoenvironmental•EnergystoragesystemsCustomerdescriptionstewardship,havecreatedaculturethatdrives•CleanenergysolutionsBladeVOLT®BatterySystem:DesignedspecificallyMETScompaniestoengineerpioneeringsolutions•Renewableenergygridintegration3METechnologyoperatesthroughapartnershipforsafety-criticalsectors,BladeVOLT®thatprioritisesustainability.•Energyefficiencymeasuresmodel,collaboratingwithseveralAustralianandensuresprotectionagainstthermalrunaway•ElectrificationinternationalminingOEMs,prominentminersandthreats,makingitsuitablefordemandingThroughinnovation,adaptabilityandadeep•Hydrogenfueltechnologiescontractors.Theycurrentlyexporttheirbatteryenvironmentslikeundergroundminingandairunderstandingoftheindustry’sintricacies,•Renewableenergytechnologiesforsystemsglobally.Thecustomerinthisexamplecargotransportation.AustralianMETScompaniesareleadingtheisanundergroundminingvehicleandequipmentchargetowardsasustainable,greener,andmoremineoperationsmanufacturer(OEM)although3METechnologyBladeDRIVEControlSystem:Thiscomprehensiveresponsibleindustry.alsoworksdirectlywithminers.systemencompassessoftware,hardware,andelectricalcomponentsforprecisevehiclecontrol,Problemtractionsystems,andmobilepowersolutions.Asindustrytransitionstonewenergysources,aBladeNETTelemetrySystem:Offeringremote,robustbatterysupplychainbecomesessentialascyber-resilientmonitoring,BladeNETseamlesslylarge-scalebatteryuptakeisapivotalcomponentintegrateswithexistingnetworksorfleetoftheenergytransition.Themosturgentmanagementsystems.challengeintheundergroundminingsectoristhenecessitytoeliminatedieselparticulatematterBladeCHARGESystem:Facilitatinglithium-ionbatterychargingviastandardmining1000VACsources.SystemsIntegrationExpertise:TheirproprietarysoftwareeffectivelymanagessophisticatedsystemsinvehiclesliketheelectricBushmaster(3METechnologyStealthmaster®system)andundergroundminingequipment.20AcceleratingSustainableMiningAcceleratingSustainableMining21CaseStudyElectricpersonnelcarriervehiclesforundergroundminesCompanynameCustomerdescriptionAmpcontrolThroughcollaborationwithjointventurepartners,Ampcontrolsolvestheworld’smostcomplextheUniversityofNewcastle,ResTech,andproblemsinenergythroughcollaboration,Solitech,AMPCONTROLhasdevelopedDRIFTEX,developingleadinginnovationsthatpushaBatteryElectricPersonnelCarrierVehicle(BEV),industrytodecarbonise.Itcreatesworld-firsttomeettheenvironmentalandsafetyneedsofenergysolutionsofscaleusinginnovationundergroundmines.partnerships,smartpeopleandadvancedAustralianmanufacturing.AmpcontrolseekstoProblemleadtheglobalenergyrevolutionandmakenetzeroarealityforallindustries.Withagrowingandimmediateindustrydemandforlowemissionstechnology,theundergroundExperiencedEngineeringTeam:Theirteam’s•Achievedlowertotalcostofownership(TCO)miningindustrywasseekingasolutiontoeliminateexpertisespansmechanical,electrical,software,throughsignificantlyreducedmaintenanceanddieselemissionsinundergroundapplications,hardware,andsystemsintegration,ensuringoperatingcostssupportingfewerventilationrequirementsandcomprehensivesupport.reducingnoise.•SupportedeffectivechangemanagementEstablishedFieldServiceCapability:3MEwithappropriateriskmanagement,trainingDRIFTEXcameintodevelopmenttoaddressTechnologyoffersrobustfieldservicesupportforandsolutionsthatminimiseimpactonworkersburgeoninghealthandsustainabilityconcernsfieldtrialsandtesting.andoperations.forminersandtoreducethegrowingamountofdieselemissionsexperiencedacrosstheminingindustry.ResultsContactwww.3me.technologyThroughimplementinga3METechnologyinfo@3me.technologycustomisedsolutiontheOEMwasabletoofferminersasolutionthat:•Improvedhealth&safetyundergroundthrougheliminatingdieselparticulatematter(dpm)andreducingnoise,heatandvibrations•Supportedmeetingdecarbonisationgoalsandprogressingtowardsallelectricminingoperations22AcceleratingSustainableMiningAcceleratingSustainableMining23SolutionTheDRIFTEXinnovationwonanawardforHealthAustralianMETSCapabilitiesExcellenceatthe2023NSWMiningHealth,TheZeroCarbonMineDRIFTEXisaBatteryElectricVehicle(BEV)Safety,EnvironmentandCommunities(HSEC)designedforuseinundergroundminingAwards.Carboncaptureapplications.Thisworld-firstinnovationandstorageincorporatesa60kWhintrinsicallysafebatteryDRIFTEXhasprovidedpositiveoperationalEnergystoragemanagementsystemwhichprovidestenyearsofimpactstotheminingenvironmentthrough:systemsoperationinatypicalusecycle.Cleanenergy•reductionindieselparticulates/dieselsolutionsDRIFTEXseamlesslyintegratestoanystandardparticulatefilters,RenewableenergyEVcharger,notrequiringproprietarychargegridintegrationequipment.Thebattery’scoolingsystemsupports•reductionindieselusage(decarbonisation,Energyefficiencyfast-chargingcapability,enablingafullbatteryoperationalexpenditure),measureschargein10minuteswithhigh-poweredDCfastElectrificationchargers.•wholebodyvibration(WBV)improvements,Hydrogenfuel•noisereduction(hearingprotectionisnolongertechnologiesDRIFTEXoperationaladvantagesincludeRenewableenergymulticolourintrinsicallysafeheadlights,IoTrequired),technologiesformineconnectivitytoimproveoperationmaintenanceoperationsandfaultfinding.DRIFTEXhastwo100kW•improvedergonomicsanddrivervisibility,motors,withacombined1500Nmofoutput•equivalentcharge/refueltime,eliminating3METechnologytorque.Ampcontrolconcernoverchargetimes,AntrakLogisticsResultsCarbonNeutral•bettermonitoringandfaultfindingtoolswithDecarbifyReduceddieselemissionsandnoiseresultinfullinstrumentation,DGaSServicesgreaterprotectionofworkhealthandwellbeingEarthSystemsaswellasreducedundergroundventilation•IoTleadingtodriverassistanceaids,thebasisElwaEnergysaverscosts.Thistechnologysupportsthereductionforautonomousvehicle,realtimemonitoring,GaletechAustraliaofsiteenvironmentalemissions,contributinglocationidentification(emergencyresponse),GekkoSystemstoimprovementsinthesociallicenceandGHDsustainabilitygoalsofthemine.•improvedlighting,GloboHydroPower•easeofcustomisationtositespecificGreenGravityTheinclusionofIoTcapabilityenablesconnectivityHansonAustraliaandenhanceddatacollectionforefficientrequirementswitheverythingmonitoredandKiTechHydrogenSystemsmonitoringandmanagement.Moreover,userscustomisableinthesoftwareLightningProtectionhavetheflexibilitytocustomisethetechnologyInternationalaccordingtotheirspecificrequirements,resulting••reducedmaintenanceandinspectionsasMagnumAustraliainanetzeropathway.monitoringsystemidentifieswhenrequired.MinnovareOptrixContactRWDIwww.ampcontrolgroup.comScantechInternationalmarketing@ampcontrolgroup.comUndercon24AcceleratingSustainableMiningAcceleratingSustainableMining25SustainableMining:CaseStudyTheSmallFootprintMineOptimisingtheenvironmentalfootprintofmineralextractionIPJCASESTUDY:RecoveringtinattheAlphaminResources–BisieTinprojectBackgroundProblemTheBisieTinundergroundprojectWholeoforeprocessingwasgoingtopotentiallyislocatedinWalikaleDistrict,challengetheproject’seconomicviability.TheminesoughttomakethetinprocessingoperationCompanynameasefficientandenvironmentallysustainableaspossible,whilereducingcapitalandoperatingGekkoSNysotretmhsKivuProvinceofthecoststoensureeconomicprofitmargins.DemocraticRepublicofCongoAlphaminResourcesisalow-(DRC).Bisieisoneoftheworld’scosttinconcentrateproducerGekkoSybsitgegmestistaingldoebpalolesaitdse.rinmineralfromitshigh-gradedepositatprocessing,providingfullyintegratedsolutionsMpamaNorthandanadditionaltomininAglcpohmapmaniniesRaersoouunrdctehsehwoolrdlds.8O0v.e7r5%thepasts2ta5kyeeairns,tGheekpkorohjaescdtetvherloopuegdhsittrsong5explorationlicensescoveringcapabilitsiuesbisnidthiaerdyesAiglpnh,mamaniunfaBcitsuierinMg,ininginstallat(iAonBaMn)d,cwohmimleistshioenDinRgCofGeonveergrynmentatotalof1,270km2intheNorthefficientamnoddIunladrumstinriearlaDlpervoceelosspimngeenqtuipmentandcomCpolertpeoprlaantitosnfoorfaSwoiduethraAnfgreicoafmhoinledralsKivuProvinceoftheDemocraticincludinggold,silverandpolymetallics.RepublicofCongo(DRC).5%and14.25%,respectively.Miningorganisationswillneedtofundamentallyre-thinkwhataminingoperationlooksAlphaminisheadquarteredinConstructionwasstartedin2018like,transformingtraditionalcapital,resourceandenergyintensivepractiMceasuraintidusandlistedontheTSXCustomearnddesccormiptpiolentedinthefirstquarterproceduresasweprogresstoamoresustainableminingindustry.AlphaminofRe2s0o1ur9c.esBisieTinMineisalow-costtinVentureExchange(TSXV:AFM)concentrateproducerintheNorthKivuProvinceandtheJohannesburgStockoftheDeTmheocBraistiiceRTeipnupblricojoefcCtoinsgboe(DinRgC).AustralianMETScompaniesarepioneeringnewAustralianMETScompaniesarediEsrxucphtainnggteheAltX(JSEAltX:APH).developedinthreephases.Thefirstphasefocusesondevelopingthewaysofminingfortheircustomersacrossthestatusquointheminingindustry.TheyofferMpamaNorthregion.MpamaNorthglobethatreducesthepotentialimpactandsizeisproducingapproximately10,000ofminingoperations.Alphaminareaimingtoincreasetonnescontainedtinperannum.Itslifeofmineiscurrently12.5years.Advancedvisualisationtechnologies,powerfulexpertisethatwillreducethesizeandimpactssensorsandnavigationtoolsarebeingutilisedThesecondphaseisunderwaytoidentifyandpreciselyextractthemostfertileofminingoperations,includingmeathnonduoalolgtiiensoutputandlifeofwiththeIPJformingpartoftheorebodies,eliminatingwasteandreducingcostsinofagileminedesign,in-siturecovemryi,nloewtihmrpoaucgthincrementalnewplant.thisprocess.processing,biodiversitymonitorinpgraonddulacntidonfromMpamaSouthAustralianMETScompaniesareworkingwithcustomerstotransformmanagerialmindsetsreclamation.andbyaddingmoreminesinandchangeoperationalculturetocreatemoreagileandmodularminedesignsthatleveragecloseproximitytothecurrentadvancementsinmanufacturingandsimulationsoftware.Keybusinesscapabilities:productionandfromwithin•Agileandmodularminedesigntheirlicensedfootprint.•Precisionminingtechnologies•In-siturecoverytechniques•Lowimpactprocessingmethods•GreenminingpracticesCutting-edgetechnologiesanddeepdomain•Ecosystemrestorationgekkos.comknowledgearebeingutilisedtoreducethelasting•Biodiversityconversationimpactofminingoperations,restoringcritical•Landreclamationecosystemsandrehabilitatingland.26AcceleratingSustainableMiningIPJCASESTUDY:AcceleratingSustainableMining27RecoveringtinattheAlphaminResources–BisieTinprojectRoMOreClosedCircuitScreen-10mmGrizzlyCrushers1mmScreenasJawmetalCrushercludedStockpilePJmfrom-1mm-10+1mmiseenSolutionJigTailingsResultsCaseStudyvedTSFModularconstructioninremoteareassolvingsafety,powerandwaterchallengesfromUtilisingitscompacRtodInMiLllinePressCuonrceentJraitgeM-1(i0IllP6µJm)Significantlyreducedcapitalandoperatingcoststhe2Stage-425µmSulphideJiggingFlotationdtheGekkoSystemsintroducedapre-concentrationandincreasedprocessefficiencieswereachievedintoTinConcentrate-1mmbypreSMcepaoagrnnaetticoicnentratingthefeedoreusingtheIPJ.circuittothetinproceSspsirailngoperation.ircuit.ConcentratorsTailingsMillde-106µmH.G.TinConcofTheIPJcircuitreducedthemasstotheImprovementsFilitnractiolnuded:andducedownstreamconcHe.Gn.Ctonrcaenttroatrewhileretaining>90%•97%tinrecoveryheSulphideofofthemetalSpiralthroughgravitypre-conceFnlottartioantionTinH.G.andeateConcentratorsFlotationTinConcentrateedtostage.Thepre-concentrationprocessreducTeindFlottahtioenTails•20%reductioBanDgegsiipnnagtcaehndnergyuseoughdownstreamconcentratorfeeL.Gd.Cfonrcoenmtrate57tonnes•10%reductioninwaterusenumerouscountriestodeliverreliablesolutions.perhourto9tonnesperhour.fortheirclients.TheyarealsoknownfortheredL.G.TinConcabilitytosuccessfullytransfertechnologiesandThisreductioninthesizeoftheTcaiolinngscentratorinnovativetechniquesacrosscommodities.assignificantlyreducedthemassofchemically•FiltrLataionrgeportionofchemicalfreesand-liketailingsmetalCustomerdescriptioncludedthatTcSFanbere-usedonsiteTheByerwenmineprojectcontinuesSedgman’sPJcoFnitgaumrein2a.tPeladnptlParnotcreesssidFluoew.Diagram•CapitalandoperatingcostsavingsoflonghistorywithQ-CoalGroup.Since1989,mfromapproximately50%Q-CoalGrouphasbeenanindependentQueensland-basedcompanythathasbeenactiveisOriginalIPJProcessFlowDiagramContactCompanynameintheQueenslandResourcesSector.TheByerweneenwww.gekkos.comSedgmanplantproducesasteel-makingcoalandathermalIPJFeed14gekkos@gekkos.comcoalproduct,maximisingthevalueobtainedfromvedSedgmanistheleadingproviderofintegratedtheresource.Sedgmanwasinvolvedinmultiple3FinalTailmineralsprocessingsolutions.Since1980,stagesofthefacilitydesignandconstruction,fromSedgmanhaveadvancedthestandardofincludingthetrainloadoutfacility,stage1and2theHutchWater2511excellenceandinnovationindesign,deliveryandprocessingfacilityscopes,andarecenttailingsoperationsforclients.TheirAustralianheritagedewateringfacility.Inaddition,Sedgmansupportsdthe8hasturnedintoalegacyofprojectsaroundtheQ-CoalGroupthroughoperationsservicesforintoworld,andtheyhaveexpandedfromtheirearlythefacility.-1mm69daysincoaltotoday,wheretheirexpertiseincludesironore,preciousandbasemetals,ircuit.712FinalConslithium,potash,sodaash,andindustrialminerals.d10Sedgmanactivelyusesdataandknowledgeegainedacrossfourdecades,hundredsofFlowTPHSn%processingandmaterialshandlingprojects,and1–IPJFeed574.312–IPJFinalCons925-30Figure3.IPJProcessMassBalanceFigure4.IPJGravityBoxOverallPlantProcessFlowDiagram1mmScreenRoMOreClosedCircuitScreen-10mmGrizzlyCrushersJawCrusherStockpile-1mm-10+1mmJigTailingsTSF2StageRodMillConcentrateMillSulphideMagneticJigging-425µm-106µmFlotationSeparationSpiralSpiralTailingsMillTinConcentrateConcentratorsConcentrators-106µmH.G.TinConcFiltrationH.G.ConcentrateSulphideTinH.G.andFlotationFlotationTinConcentrateTinFlotationTailsBaggingandDespatchL.G.ConcentrateTailingsL.G.TinConcFiltrationTSFFigure2.PlantProcessFlowDiagramAcceleratingSustainableMining2928AcceleratingSustainableMiningOriginalIPJProcessFlowDiagramproduction.StagedexpansionalsoallowedCaseStudyimprovementstodesignwhentheprocessingfacilitywaslaterduplicated.Progressivelandrehabilitationdeliveringindustry-leadingoutcomesProblemExcellentsafetyoutcomeswereachievedintheCompanynameCustomerdescriptiontailingsdewateringprojectscope,withSedgman’sThiessRehabilitationQ-CoalGroupapproachedSedgmantoaddressdeploymentoftheself-performconstructionMACHEnergyAustralia’sMountPleasantaseriesofchallengesattheirByerwenproject,workforce,whichprovidestheirclientstheThiessRehabilitationofferscomprehensiveOperation.MountPleasantOperationisarecentlyanopencutmineintheNorthernBowenBasin,benefitsofreducedprojectcost,highsafetyminerehabilitationservicesforsitesofallestablishedhigh-qualitycoalmineintheHunterQueensland.Minimisingconstructiontimeframes,standardsandculture,excellentqualityandsizes,commodities,requirements,andlifecycleValley,NewSouthWales.ensuringthesafetyofconstructionteams,andproductivitythroughanexperiencedconstructionstages.DeliveredbyminerswithenvironmentalminimisingcapitalcostsweredriverstowardsworkforcefamiliarwithSedgmandesignandexpertise,theirservicesincludeprogressiveProblemmodularconstructionforthissite.Logisticsandprocedures.minerehabilitation,mineclosure,infrastructuresafetychallengesareevenmorepronouncedforremoval,abandonedmines,andcontaminatedThesiteisveryclosetothetownofMuswellbrook,projectswhichareremoteanddonothavelocalToaddressthepowerreductionchallenge,thelandrequirements.ThiessRehabilitationhasandtheprojecthassomeofthemoststringentskilledworkforces.Inaddition,projectchallengesmodularfacilitydesignwasbasedonmaximisingindustry-leadingcapabilityinenvironmentalandenvironmentalrequirementsinNewSouthWales.includedminimisingpowerandwaterusage.useofgravityintheprocessingcircuits,toreducecivilengineering,landformdesignoptimisation,Progressiverehabilitationfromthebeginningofpowerusage.advancedsurveying,assetmanagementtheproject,ongoingcommunityengagementandSolutionandmaintenance.deliveringexceptionalenvironmentaloutcomesOneofSedgman’skeyservicesistailingshasbeencriticaltotheproject’ssuccess.Sedgman’smultidisciplinaryengineeringanddewatering,whichmaximiseswaterrecovery,projectdeliveryteamsworkedtogethertoandreducesthelikelihoodofenvironmentalSolutionaddresstheoutlinedchallenges.Cost,scheduleharmassociatedwithtailingsdams.In2022andsafetydriversweremetthoughtheirmodularSedgmandeliveredanengineering,procurementThiessRehabilitationprogressivelyrehabilitatedconstructionapproach.andconstructioncontractofanewtailings60hectaresoflandatMountPleasantOperationdewateringfacilityattheByerwenmine.Thisfromthebeginningofthemine’soperations.Forbothstage1andstage2processingfacilityprojectconvertedtheexistingwetrejectsFocusedonmirroringoriginalnativelocalhabitatconstruction,allstructuralsteelwasfabricatedpumpedco-disposalsystemtoacombineddryandcreatingenduringenvironmentalvaluetotheoffsite,wheretheirteammanagedthefabricationtailingsandcoarserejecttruckedsystem.Theclientandthecommunity,ThiessRehabilitationprocess,ensuringahigh-qualityproductwasnewsystemisanintegratedelementoftheincorporatedmorethan354habitatfeaturesintomanufacturedtotherequiredqualitystandardsByerwenmineexpansionandresultsinalowerthelandscape.andsecurelyloadedandtransportedtoAustralia.operationalriskprofile,lesspowerusageandSedgman’strustedpreassemblysubcontractorimprovedwaterrecoveryandmanagementofWorkingcloselywiththeclient,theteamadoptedcompletedtheassemblyofmodularsteelworkdewateringchemicals.afluvialgeomorphiclandformdesigntoensureincludingtheinstallationofmechanicalandlong-termstabilityagainsterosionandbuildelectricalequipmentwithothercomponentsatResultsthefoundationtoestablishself-sustainingtheMackaypreassemblyyardanddeliveredtoecosystemspostmining.theByerwenminingsite.ByusinganinnovativeReducedconstructiontimeframes:Forthefirstmodulardesign,theysignificantlyreducedfacilitybuilt,moduleswereliftedintoplacewithinTheteamidentifiedareaswhererehabilitationconstructioncost,onsiteworkforcenumbersandeightdays.couldconnectmorecloselywiththebroaderoverallprojectduration.ModularconstructionlandscapeandworkedtocreatewildlifecorridorssignificantlyreducessafetyrisksthroughlowerExcellentsafetyoutcomes:Themodulartofacilitatethemovementoffauna.Thisworkon-siteconstructionhours,andreducedworkingconstructionoftheprocessingfacilitieswasincludedplantingtreeswithhollows,creatingatheights.Thereductioninconstructionscheduleexecutedwithzerolosttimeinjuries.landcrevicesandscatteringloosebarkandtimeframesalsosupportedfastertimetoinitiallargebranchestocreateanaturalhabitatforPowerandwater:Thenewsystemisintendednativespecies.toresultinaloweroperationalriskprofile,lesspowerusage,andimprovedwaterrecoveryThedesignoutcomesmetend-of-land-useandmanagementofdewateringchemicals.objectives,compliedwithregulatoryobligationsComparedtorawwaterusagepriortoinstallation,andaddressedlong-termclosurerequirements.theByerwendrytailingsdesignispredictedtosavearound1.2millioncubicmetresofwaterperannum–equivalentto492Olympicswimmingpools.Contactwww.sedgman.commail@sedgman.com30AcceleratingSustainableMiningAcceleratingSustainableMining31Thistailoredsolutionmettheirclient’sneedsTheresultingopen,grassywoodland,withAustralianMETSCapabilitiesandenabledthemtooptimisetherehabilitationnativegrasses,treesandshrubs,incorporatesTheSmallFootprintMinedesign,reducingtheiroperatingcostswithoutconnectedhabitatsthatcreatewildlifecorridorscompromisingquality.withthesurroundinglandscape,encouragingtheAgileandmodularreturnoflocalfauna.minedesignItalsoinformedtheirapproachtouseejectorPrecisionminingtruckstohaulandplacetopsoilandtailorseedInparticular,thegeo-fluvial,naturallandform,technologiesmixestobettersuitthefinallandscape,includingincludingcontours,peaksandvalleys,lookslessIn-siturecoveryareaswithincreasedstabilisationrequirements.engineeredandmorevisuallyappealing,withtechniquesbetterlong-termlandformstability.Low-impactResultsprocessingmethodsContactGreenminingTherehabilitationprocessesundertakenatMountwww.thiessrehabilitation.compracticesPleasantOperationshavebeenrecognisedasinfo@thiessrehabiliation.comEcosystemindustry-leadingbytheNSWResourceRegulator.restorationBiodiversityThefirstrehabilitationcampaignwasdeliveredconversationtwomonthsbeforethefirstcoalwasminedLandreclamationandsevenmonthsbeforethefirstcoaltrainwasloaded.AustralianCrushing&BeltingGroupConceptEnvironmentalServicesDynamicsG-ExEarthTechnologyFleetSpaceTechnologiesGekkoSystemsGeoMobyGlencoreTechnologyGloboHydroPowerLightningProtectionInternationalMineralTechnologiesOffWorldAustraliaOwenCustomProductsRealTimeInstruments(RTIAustralia)RemBindSedgmanSouthernInnovationSpaceDraftThiessRehabilitationUnderconXencoServices32AcceleratingSustainableMiningAcceleratingSustainableMining33SustainableMining:CaseStudyTheWasteFreeMineInnovativetechnologyforrecoveryofmetalfromlowgraderesourcesIntheglobaldrivetoefficientlyextractmineralsfromorebodiesmoreCompanynameProblemsustainably,miningcompaniesareincreasinglyfocusedonwasteCoreResources/CoreIPEXreductiontechniquesandtechnologies.DevelopmentandimplementationofnewCoreResourcesisaspecialistdeveloperoftechnologytorecovervaluablemetalsfromprocessesandtechnologiesforthecleanandlow-tenorleachatesfromvanadiumcalcinesustainableproductionofminerals,withafocusdumps.Inaddition,thedevelopmentofimprovedonthecriticalmineralsthatwillbeessentialpurificationmethodstoproducehighpurityendfortheworld’senergytransition.Corehasaproducts,suchaselectrolyteforVanadiumRedoxpartnershipwithSouthAfricantechnologyFlowBatteries(VRFBs),atacompetitiveprice.companyIPEXtofurthercommercialiseinnovativehydrometallurgicaltechnologiesSolutionusedfortherecoveryofmetalvaluesfromlowgraderesources.CoreIPEXimplementedtheirnovelionexchangetechnologytorecovervaluablemetalsfromCustomerdescriptionthelow-tenorleachatesatvanadiumcalcineAmajorprimaryvanadiumproducerindumps.IonexchangeisaprocesstypicallyusedSouthAfrica.extensivelyinthewastewaterindustrythathaswiderangingapplicationsintheminingindustrytoAustralianMETScompanieshavedevelopedaasuneconomic,alleviatingtailingschallengesrecovervaluablemetalsfromsolution.rangeoftechnologiesandpracticestoreduceandmakingthemostofthematerialsthathavewastefromtheminingprocessandre-useittoalreadybeenextracted.Theprincipleofionexchangeforminingcreatevaluablenewproductsandmaterials.applicationsisthatcertaindissolvedmetalsAustralianMETScompaniesarepromotingainsolutioncanbeselectivelyrecoveredontoaDeeporebodyknowledge,cutting-edgeorewastefreeminingindustryandadoptingsmarttargetedresinoverotherdissolvedelementssortingtechniquesandin-pitcrushingandprocedurestopromotecirculareconomymodelsinsolution.Therecoveredmetalscanthenbeconveyinghavebeenutilisedtoremovewasteintheminingindustry.Theyofferexpertisesuchstrippedofftheresinbycontactwithacidorfromtheminingprocess,eliminatingtheissueatasadvancedresourcerecovery,repurposingofitssource.wasteforconstructionmaterials,wastedisposalandbestpracticetailingsmanagement.Tocombatcurrentwastechallenges,innovativemethodologieshavebeenimplementedtoturnKeybusinesscapabilities:millionsoftonnesofminetailingsandwasterock•Waste-to-energytechnologiesintovaluablematerialssuchasgreencement,•Waste-to-constructionmaterialsprocessesbricks,ceramicproductsandroadbases.Thishas•Sustainablewastemanagementpracticesopenednewmarketsandrevenuestreamsfor•Tailingsmanagementminingorganisations.•Resourcerecoveryandreuse•CirculareconomymodelsforminingAdvancedprocessingtechnologieshavethen•Wastedisposalandremediationbeendeployedtorecovervaluableresourcesandcriticalmineralsthatwerepreviouslyidentified34AcceleratingSustainableMiningAcceleratingSustainableMining35alkalitogenerateaconcentrated,purified,furtherreducedimpuritytracestodelivervanadylCaseStudymetalsolutionstreamforfurtherprocessingtosulphatesolutionofclosetoultra-pure“foursaleableproducts.nines”(≈99.99%grade).RestoringevaporationpondstoragecapacityThispremiumqualityelectrolyteisproducedatResultssignificantlylowercostscomparedtoconventionaltheconsolidationandlocationofthesolidswithinprocessingalternatives.thepond,theslurrywasconsideredtobetoowetCoreIPEX’snovelionexchangetechnologyinitiallytoremovewithexcavators.producedvanadylsolutionsataround99.6%Contactgrade.Impuritylevelswerefurtherreducedbywww.coreresources.com.auupgradingequipmentusedforcycletransitionrcoleman@coreresources.com.aurinsingwhichachieved>99.9%puritylevels.CompletedemineralisationofprocesswaterCompanynameSolutionGeofabricsAustralasiaGeofabric’sGeotubeDewateringcontainersareGeofabricsworkstoprotect,containandsecureapassivemeanstodewateranddrysludgesthephysicalenvironmentusingsmartgeotextilewithoutsignificantcapitalexpenditure,whichcanandgeosyntheticproducts.Forover40years,betypicalofmechanicaldewateringmethods.GeofabricshasbeenhelpingclientsmitigateInthiscaseGeotubeunitswereselectedandenvironmentalriskthroughworldleadingusedtocapturedredgedsolidsanddrythemtoaresearchandinnovativeproductdevelopmentinspadableconsistency.keyinfrastructuresectorssuchasmining,waste&containment,road,railanddefence.CustomerdescriptionKestrelmine,locatedinCentralQueenslandisoneoftheworld’slargestmetallurgicalcoalmines,producingaround7milliontonnesofmetallurgicalcoalannually.Since2018,KestrelCoalResourceshasoperatedthemineandissupplyingcoaltokeymarketsaroundtheworldtobeusedinthesteelmakingprocess.ThecompanywasawardedtheAustralianMiningMonthly(AMM)MineoftheYearin2019withitscapabilitiescoveringtheentireminingprocess,fromdevelopmenttoextractionandprocessing,environmentalmanagement,andsustainablerehabilitation.ProblemContainersaredeployedonsitewithinanavailablefootprinttocaptureanddewatersludgeTheprimaryobjectivewastorestorethestorageinaconfinedfootprintcomparedtoopen-aircapacityoftheexistingevaporationpondsatthedrying.ExposingdriedcoaltoweatherindryingKestrelminesite.Priortodredging,theHDPElinedbedscouldleadtolesscontroloverthespoilevaporationpondhadaccumulatedcoalfinesasandanincreasedriskofre-saturationduringaresultofthesitewastedisposalprocess.Thisrainfallevents.resultedinlimitedstoragevolumeavailabletofacilitatetheevaporationoftheeffluent.Dueto36AcceleratingSustainableMiningAcceleratingSustainableMining37GeotubedewateringprovidedtheclientwithCommonlyflocculantsareintroducedwithCaseStudyacost-efficientsolutionfordryingsolidsonfinesolidswhendewatering,butinthiscasesiteallowingthedredgingoperatortopumpwasavoidedduetocost.ThedecisionwasReducingwasteandwaterfromtailingsdamsandoperateatextremeflowratesthatweremadetointroduceflocctoimprovedewateringcongruentwiththeirdredgingequipment.Thisperformancetowardtheendoftheproject.CompanynameSolutionmeantlesstimeonsiteandlesslabourcosts.InTheseflocculantsassistedwithmaximisingsolidsPhibionPhibionemployeditsleading-edgetailingscomparison,mechanicaldryingmethodstendretained,promotingrapidsolidsseparationandmanagementtechnologyusingAcceleratedtoslowthepumpingoperations,oralternativelydewatering,mitigatingtheriskofclogging,andPhibionisaTailingsManagementTechnologyMechanicalConsolidation(AMC™)anditsmultiplemechanicalsystemsareneededtokeepensuringhigh-qualityfiltrateclarityfromGeotube.andServiceproviderusingadvancedin-situMudMaster®dewateringequipment.upwithtypicaldredgingequipment.Asaresult,thebagsreachedtheirmaximumfillmechanicaldewateringtechnology.AMC™Process:heightsmoregradually,signifyingtheeffective•Tailingsplacedinlayers.ResultsfiltrationanddryingpropertiesofflocculatedPhibion’svisionistomaketailingsdamssafer,•MudMaster®ploughslayerfromthepointofsolids.Consequently,thelabourinvolvedinsmaller,andmoresustainable.Thesolidwithinthepondwashydraulicallyre-managingflowswasalsoreduced.Theflocculateddepositiontothepointofwaterrecovery.saturatedintoaslurryandpumpedintotheGeotubecontainersprovidedgreaterconsistencyCustomerdescription•Waterisforcedtothesurface,collectinginSolmaxGeotube®dewateringcontainer.infinalfillheights,allowingthestackingofbagsifdesiredandwhenproperlyconfigured.LynasRareEarths–MountWeldMineisararescrolltracksanddrainingtowaterrecovery25Geotubecontainersmeasuring18mwideearthmineandprocessingrefineryatMtWeld,point,whereitcanberecycled.x30.6mlongweredeployedonsiteandwereGeotubeprovidedtheclientwiththemost750kmnorth-eastofPerth,WesternAustralia.•Processrepeatedinacycleuntiltargetdensityusedtodewaterapproximately20,000m3ofcost-efficientsolutionfordryingsolidsonsiteThismineisgloballyrecognisedasoneoftheorstrengthachieved.coalfines,witheachGeotubecontainerholdingwithconsiderationtothehighflowratesfromworld’spremierrareearthdeposits.•Newtailingslayerisdepositedandapproximately850m3ofcoalfines.Pumpingfillthedredge.processrepeats.heightswereapproximately2.3m,withGeotubeProblemTheInternationalAluminumInstitutehasselectedunitssettlingtoapproximately1.6moncedriedContactPhibion’ssolutionasoneofthebestavailableandafterpassivelyweeping.www.geofabrics.coIntheearlydaysofproduction,theMtWeldtechnologiestomanagetailingsorresidueofb.lewis@geofabrics.com.autailings,comprisinggangueminerals,unrecoveredbauxiteandaluminaprocessing.rareearthmineralsandwaterfromtherareearthflotationprocess,didn’tsettleandconsolidate,Mudmaster®leadingtotherapidfillingoftailingsstoragefacilities,stabilityissues,andneedforanexpandingtailingsfootprint.Establishedtechnologieswerenotsuitableduetoacombinationofcapitalexpenditure,operationalcost,andtechnicalrisk.Analternativesolutionwasneededtosolvethemine’stailingsmanagementchallenges.LynassoughtassistancefromPhibiontoprovideabespoketailingssolutiontomanagetheuniquerareearthtailingsproperties.38AcceleratingSustainableMiningAcceleratingSustainableMining39Resultsforfullimplementationandwithlessthan50%ofAustralianMETSCapabilitiestheenergydemand,whilesignificantlyreducingTheWasteFreeMineTheimplementationofAMC™hasbeencarbongeneration.transformational.ImprovementstothetailingsWaste-to-energyoperationsinclude:Withthesignificantincreaseinfinaltailingstechnologiesdensity,thisledtotheunusualmetricofzeronetWaste-to-construction•A50%reductionintailingsvolumethatneedsincreaseinstoredtailingsvolumefor3years,evenmaterialsprocessestobestored.withcontinuoustailingsdeposition.Sustainablewastemanagementpractices•A100%increaseinthemaximumtailingsContactTailingsmanagementdensitythatcanbeachieved(from0.65t/m3towww.phibion.comResourcerecovery1.2t/m3).info@phibion.comandreuseCirculareconomy•Anincreaseintheshearstrengthtoovermodelsformining30KPa(whichsupportsloadbearingmachineryWastedisposalandforrehabilitationandclosure).remediation•ThetailingsstoragefacilitiesfillingataAntrakLogisticssignificantlyreducedrate,complyingwithAustralianCrushing&Beltingregulatoryapprovals.GroupBeyondLOM•70%waterrecovery.CDSClean&RecoverThisperformancerivalswhatcanbeachievedCoreResourcesusingfiltration/centrifugationtechnologywithoutDynamicsG-Exthecapitalexpenditure,withoutthetimerequiredEarthSystemsGeofabricsAustralasiaGlencoreTechnologyGreenEcoTechnologiesHansonAustraliaK2flyOLEOLOGYPeatsGroupPhibionPitcrewAIRealTimeInstruments(RTIAustralia)RemBindScantechInternationalSouthernInnovationWorldpolyXencoServices40AcceleratingSustainableMiningAcceleratingSustainableMining41AustralianMETSListingAntrakLogisticsAustralianCrushing&BeltingGroupantrak.com.auauscbgroup.com.ausales@antrak.com.ausales@auscbgroup.com.au3METechnologyAmpcontrolAntrakLogisticsisagloballeaderininternationalAustralianCrushingandBeltingGroup(ACBG)transportandlogisticsservices,cateringisacomprehensivesolutionsprovidertomany3me.technologyampcontrolgroup.comspecificallytotheprovisionofservicesforlargeheavyindustries.Theyareknownforexpertiseinfo@3me.technologycustomerservice@ampcontrolgroup.comminingandindustrialprojects.Antrakdrawsfromincrushingwearparts,spareparts,conveyortheextensiveexperienceoftheirpersonnel,beltmaintenance,andrepairservices.Witha3METechnologyisanAustralianbatteryandAmpcontrolischallengingthefuturebysolvingtheresourcesoftheirglobalnetwork,anddeeprichhistoryspanningovertwodecades,ACBGheavy-electric-vehicletechnologycompanybasedthemostcomplexproblemsinenergy.AmpcontrolunderstandingofprojecttransportandlogisticshasevolvedintoatrustedpartnerforclientsinCardiff,NSW.Theydesignandmanufacturecreatesenergysolutionsofscaleusinginnovationservicestoprovidecustomisedsolutionsthatacrossdiverseindustries,includingmining,safe,energy-dense,lithium-ionbatterysystemspartnerships,smartpeopleandadvancedmeetclients’requirements,withafocusonquarrying,construction,recycling,transportation,thatpowermininganddefenceequipment.Australianmanufacturing.Theirvisionistoleadcost-effective,safe,andon-timedeliveryofallanddefence.3ME’sbatterytechnologyenablestheirminingtheglobalenergyrevolutionandmakenetzerocargo.Antrak’scommitmenttotheirContinuouscustomerstoreplacediesel-poweredvehicleareality.Everyday,theworld-firstinnovationsImprovementCharterandserviceoptimisationValuepropositionfleetswithcutting-edgeelectricbatterysystems,fromAmpcontrolhelpandsupportcustomersreflectstheirgoalofprovidingthehighestlevelprovidingadvancedsafetyfeaturesandreliability,inallindustriestodecarbonise.WithaprovenofexpertiseinallfacetsofprojecttransportandWithselectcustomers,ACBGworktoimprovereducingemissions,improvingundergroundairtrackrecordofaward-winninginnovationsandlogisticsoperations.theircrushingwearpartsviatailoredengineeringquality,andsupportingsafer,moreefficient55yearsofdevelopingcustomenergysolutions,solutions.Inoneinstance,theyimprovedcrushermineoperations.AmpcontrolistrustedbycustomersworldwidetoValuepropositionperformanceby177%,providinganadditionalfuture-prooftheirbusiness.7daysofcrushingintheirsite.MoreefficientValuepropositionAntrakLogistics,withBolloréLogisticsascrushingreducesenergyandwaterconsumption,Valuepropositionitsparentcompanyoffersacomprehensivecandecreasematerialstockpilesizeandinfluence3METechnologyisasovereignsystemsintegratorvaluepropositionforminingcustomers.Theirtransportationrequirements.ACBGalsosourcesandhasbuiltacapabilitytodesign,manufactureAmpcontrolisunmatchedintheirtrackrecordoflowcarbontransportplansincludenetworkorproducesverydifficulttofindcrusherpartsandintegratebatterysystemsintomining,high-qualitycustomsolutionsandishelpingandoptimisation,loadconsolidation,andefficientandequipment,particularlyonoldermachines.militaryandmarineplatforms.IthascurrentsupportingitsresourcecustomerstodecarbonisetransportchoicesandaresupportedbycarbonThiscanresultinsignificantimprovementstoandfuturecapabilitiesacrossbatterysystems,withnet-zeroinnovations.footprintreports,aidinginemissionreductiontheefficiencyofexistingcrushingoperationsandsystemsintegration,remotecyber-secureassetstrategies.Antrakactivelycollaborateswithmateriallyreducingindustrywaste.monitoringandin-fieldsupport.3METechnologyPrimarySustainableMiningsub-sectorsubcontractorstodevelopalternativeenergyprovidesanend-to-endcapabilityinoff-highwayshuttleservices.ContinuousimprovementplansPrimarySustainableMiningsub-sectorelectrificationtoresourcesanddefence.AtTheZeroCarbonMinealignwithcost,deadline,andCO2reductiongoals.theheartoftheirmissionliestheeliminationofWhileexactpercentagesdependonspecificclientTheSmallFootprintMinedieselparticulatematterinundergroundmininglogistics,Antrakcanpotentiallyachievesignificantenvironments.TheyreduceemissionsattributedCO2reductionsthroughmodeswitching,multi-PrimarySustainableMiningsub-sectortodiesel-poweredvehicleswhileconcurrentlymodalsolutions,andalternativefuels.optimisingoperationsthroughtheadoptionofTheWasteFreeMineelectricmotors.WithreducedmaintenanceneedsPrimarySustainableMiningsub-sectorandfewermovingcomponents,theirinnovativesolutionpropelstheminingindustrytowardsaTheZeroCarbonMinecleaner,moreefficientfuture.SecondarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorTheWasteFreeMineTheZeroCarbonMine42AcceleratingSustainableMiningAcceleratingSustainableMining43BeyondLOMBiTQCarbonNeutralCDSbeyondlom.com.aubitq.com.aucarbonneutral.com.auconcretedatasensors.com.auinfo@beyondlom.com.auneil.jones@bitq.com.aupeter.taliangis@carbonneutral.com.auinfo@concretedatasensors.com.auBeyondLOM(BeyondLifeofMine)wasdevelopedBiTQisaDataandAIConsultancywhosepurposeCarbonNeutralhelpsbusinessesintegrateCDSisafullyownedandoperatedBrisbane-toassisttheminingandresourceindustrytoistomakedatauseful.Thisencompassesstrategiestomitigatetheclimatecrisis.Thebasedtechnologystartupprovidingworldclassmeetthechallengeofbalancingeconomicreturnreportingandanalysis,datagovernancecarboncycleanditseffectonclimateiscomplex.wirelessdatasensorstodetectfailuresbeforewithsustainability.Throughinnovationandimplementation,datastrategy,dataengineering,Theirroleistoprovideabetterunderstandingtheyhappen.CDSsensorsusestateoftheartengagement,BeyondLOMaimstotransformdatavisualisationandofcoursedatascience.ofwhat’sinvolvedandhelpclientsimplementtechnologyandAItodetectpotentialcollapsessotheminelifecycleintoaconceptthatbenefitsBiTQhasmanyyears’worthofexperienceacrosssimplersolutionstoreducetheirimpactonthetheyprotectpeople,propertyandassets.investors,communityandtheenvironmentalike.theminingsector,withnumerousminingclientsclimate.Theyhelpwithconsultancy,assessmentsWithacombinationofpassion,drive,firstnationthroughoutAustralia.andreporting;buyingcarbonoffsets,tailoringValuepropositionownershipinthebusiness,extensivepersonnelacarbonoffsetsolution,projectdevelopmentexperienceandin-depthconsultation,theirteamValuepropositionservices,andbuyinghighvolumecarboncredits.CDSsensorsmonitorwaterstoragefacilitiestodevelopsintegratedsolutionsfornewandexistingTheyoffercarbonmanagementservicestoensurethatthereisnolossofwaterthroughmineleases.WithafocusonthefutureoftheTransitioningtoadatadrivenoperatingmodel,organisationsacrosstheglobe,supportingacollapseandfailuresofthestoragestructure.Theindustry,theyhelptransitiontowardaminingefficienciesareattainedbyleveragingthepowerdiverserangeofclientsfromindividualsandsmallsamesystemisusedtomonitortailingsstorage.modelthatmaximisesefficienciesandenhancesofthedata,notjustinhavingthedata.BiTQbusinessestolargecorporateemitters.Bystoppingleaksandfailuresthroughmonitoring,sustainabilityduringandbeyondthelifeofamine.enablesvaluableoutcomesthatarederivedCDSsensorsremovetheneedtoimport30,000fromharnessingthepowerofthevastamountValuepropositionlitresofwaterbytruckweeklyper50millionlitresValuepropositionofdatathatexistswithinthetypicalminingofstorageundermonitoring.companies’ecosystem.BiTQensureminersstayCarbonNeutralprovidesthenetworksupportBeyondLOMvalueaddstopreviousandexistingaheadofthecurvebycreatingdatathatenablestohelpbusinessesintegratestrategiestoPrimarySustainableMiningsub-sectorminingoperationsbyrepurposingliabilities.minerstoeliminateunnecessaryfunctions,andmitigatetheclimatecrisis.TheyhelpbusinessesForexample,turningtailingsintoassetsandmoreefficientlymanageandreportontheiridentifycarbonfootprintreductionscustomisedTheSmartWaterMinehencegeneratingnewrevenuestreamsforthesustainabilitypractices.Throughpartnershipsforindividualcompanystrategyandscopeinminerandthecommunitysupportingit.Eachwithleadersinthesoftwareindustry,BiTQadditiontoprovidingcarbonoffsetopportunitiesSecondarySustainableMiningsub-sectorsitewillhavedifferentopportunities.Engagingensuresdataengineering,businessintelligencetohelpcompaniesmeettheUNSustainableBeyondLOMandtheirecosystemofspecialistanddatascienceisworld-class.DevelopmentGoals.TheWasteFreeMinedeliverypartnersensuresallviableoptionsareputonthetablewithflexibleimplementationPrimarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorandcommerciality.TheCommunityMineTheCommunityMinePrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorTheWasteFreeMineTheZeroCarbonMineSecondarySustainableMiningsub-sectorTheSmartWaterMine44AcceleratingSustainableMiningAcceleratingSustainableMining45Clean&RecoverConceptEnvironmentalServicesCoreResourcesDecarbifycleanandrecover.com.auconceptservices.com.aucoreresources.com.audecarbify.ailuke.berry@cleanandrecover.com.auinfo@conceptservices.com.auinfo@coreresources.com.aucontact@decarbify.aiClean&RecoverhelpsminingcompaniestransformConceptEnvironmentalServicesisoneofCoreResourcesisaspecialistdeveloperofDecarbifyisacomprehensivecarbonmanagementwastestreamsintoproductiveassets.TheirAustralia’sleadingprovidersofsustainableprocessesandtechnologiesforthecleanandsoftwaresolutionthatprocessesandinterpretsmissionistooffersimple,dependablesolutionsfluidsolutionsandrenewableenergysystems,sustainableproductionofminerals,withafocuscollectedsustainabilitydata,providingpredictivethatharvestvaluefromminingwastes.Theyofferingenvironmentallysensitivesolutionstotheonthecriticalmineralsthatwillbeessentialforanalyticsandinsightstohelporganisationsmakecanhelptreatacidminedrainage,andextractenergy&resource,waterandrenewableenergytheworld’senergytransition.Operatingworld-data-drivendecisions.valuablebyproductsfromminewaste.sectors,specialisinginremote,regionalandclassmetallurgicallaboratoriesandprocessurbanapplications.engineeringfacilities,CoreisrenownedforValuepropositionValuepropositioninnovation,anditsclientbaseisglobal.ValuepropositionDecarbifyisaone-stopplatformconnectingClean&Recover’ssolutionminimisesthecostofValuepropositionclientswithvarioussustainabilitypartners,treatingacidminedrainagewhiledeliveringcleanBytrulyunderstandingtheirclients’needs,products,andservices.Decarbifyhelpstowaterandvaluablebyproductsfromthedrainage.andfosteringthepioneeringspiritoftheirCoreResourcesdevelopsinnovativeandstreamlinecarbonreductioninitiativesbyTheprocessavoidstheuseofchemicalssuchasteams,ConceptEnvironmentalServicessustainablesolutionsforcomplexmetallurgicaleffortlesslyfinding,comparing,andpurchasinglimeorcausticsoda.deliverstailoredproductsandservicestoproblemsandusesitstechnicalexperiencecarboncredits,offsets,andmore,alldesignedtohelpadvanceenvironmentalsustainabilityandexpertisetotest,designandengineerthefosterasustainablefuture.PrimarySustainableMiningsub-sectorresultingin75%fasterconstructiontimethanrecoveryofcritical,baseandpreciousmetalsfromtraditionalmethods.newdepositsandfromminewaste.PrimarySustainableMiningsub-sectorTheWasteFreeMinePrimarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorTheCommunityMineSecondarySustainableMiningsub-sectorTheSmartWaterMineTheWasteFreeMineTheSmartWaterMineSecondarySustainableMiningsub-sectorTheSmallFootprintMine46AcceleratingSustainableMiningAcceleratingSustainableMining47DGaSServicesDynamicsG-ExEarthSystemsEarthTechnologydgas.com.audynamicsgex.com.auearthsystems.com.auearthtechnology.netles@dgas.com.auspencer.dormer@dynamicsgex.com.auenviro@earthsystems.com.auaccounts@earthtechnology.netDGaSServicesisadangerousgoodsconsultancyDynamicsG-ExisaninternationalgeologicalEarthSystemsisamultidisciplinaryenvironmentalEarthTechnologyprovidesminingsoftwarespecialisinginprocesssafetymanagementandsuppliescompany,thatfocusesonensuringandsocialconsultingfirm,whichdevelopsandsolutionsforallsurfaceminingoperations,facilitationoflicensingandcomplianceforprocesssmoothoperationofreversecirculationandimplementsinnovativeandeffectiveenvironment,provenover25years.Itsunique3D-Digsoftwarefacilities,majorhazardfacilitiesanddangerousdiamonddrillingprojectsthroughmanufacturingwaterandsustainabilitysolutionsthroughoutthesimulatesminingprocesses—excavation,goodslocations.andsupplycapabilities.Itshigh-qualitygeologicalworld.Establishedin1993,theyhavesuccessfullytransportanddumping—bucket-loadbybucket-fieldandexplorationproductsaretrustedbytopcompletedover500majorprojectsinAustralia,load.Using3DsimulationsolutionsforeveryValuepropositionminingcompanies,geologistsandfieldexperts.Asia,Africa,SouthAmerica,NorthAmericaandminingoperationensuresthatmineplansrunBasedinAustralia,theirreachextendsworldwide,thePacific.EarthSystemsprovideshighqualitysmoothly,beforeimplementation.Byworkingcloselywithminerstoensuretheservingdrillingprogramsacrosstheglobe.TheirservicesandsolutionsfortheresourcessectorsafehandlingofdangerousgoodsandpromotingcorestrengthliesintheircollaborativeapproachintheareasofenvironmentalandsocialimpactTheuniquedumpalgorithmrapidlysimulatesresponsibleminingpractices,DGaShelpsminingtoprojects,enablingthemtoprovidecutting-assessment,watermanagementandtreatment,multi-stagedumps.Thisallowsmaximummaterialcompaniesbuildapositivereputationwithintheedgegeologicalhardwaresolutionsofthefuture.ecology,energyefficiency,carbonaccounting,fitandtransportefficienciestobedetermined.localcommunity.Thisleadstobettercommunitycommunityconsultationanddevelopment.Simulationmodulescanoptimizeallocationrelations,increasedtrust,andsociallicenceValuepropositionofwastetodifferentequipmenttypes.Post-tooperate.Valuepropositionminingtopographyisreshapedin3D.ReshapingDynamicsG-ExspecialisesincraftingthecoreconformstodesignslopecriteriawhilebalancingPrimarySustainableMiningsub-sectorprocessingfacilitiesofthefuture,deliveringEarthSystemshelpscompaniesintheresourcescutandfill.Furtheranalysisminimizestransportenvironmentallysustainablesolutionstailoredsectortocreatesharedvaluethroughrobustdistancesfrompost-miningtopographytotheTheCommunityMinetominingandexplorationcompanies.Theirenvironmentalandsocialmanagementreshapedsurface.commitmenttoinnovationdrivesthemtothroughoutthelifecycleoftheirprojects.Theycontinuallydesignanddevelopcutting-edgealsocollaboratewithcompanies,governments,Valuepropositionsolutionsforcoreandsampleprocessing.communitiesandotherkeystakeholdersoninitiativesinarangeofareasincludinginnovationPlanoptimalrehabilitationofminedlandthrough:PrimarySustainableMiningsub-sectorandtechnologydevelopment,technicalassistanceprograms,policydevelopmentandadvocacyto•RapidreshapingwithvisualisationTheWasteFreeMinecreateamoresustainableglobalresourcessector.•Optimaltransportarrows•PumpingpondedwaterSecondarySustainableMiningsub-sectorPrimarySustainableMiningsub-sector•VisualizationtoolsTheSmallFootprintMineTheWasteFreeMinePrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorTheCommunityMineTheZeroCarbonMineSecondarySustainableMiningsub-sectorTheSmallFootprintMine48AcceleratingSustainableMiningAcceleratingSustainableMining49ElwaEnergysaversEMMConsultingEnvirosuiteOperationsEvocraelwa.com.auemmconsulting.com.auenvirosuite.comevocra.com.auinfo@emmconsulting.com.auinfo@emmconsulting.com.aumarketing@envirosuite.comsolutions@evocra.com.auELWAspecialisesinmanufacturingandEMMConsultingcombinestechnicalexpertiseEnvirosuite(ASX:EVS)isagloballeaderinEvocraisanAustralianownedwatertreatmentinstallationofenergyefficientwaterheaterunitswithadeepunderstandingofbigpictureenvironmentalintelligence.ThroughauniquecompanyofferingsolutionstoremovehazardousandLEDlightingsystems.ELWAwereanearlysustainablebusinessstrategytodeliversolutionscombinationofscienceandtechnology,contaminantsfromoftendifficulttomanageadopterofLEDtechnologyandhaveimplementedthatdrivepositiveenvironmental,economic,EnvirosuitedeliversflexiblesolutionstoaddresswatersourcestoimprovethequalityofthewaterhundredsofenergyandcostsavingLEDupgradesandsocialimpactwhilecreatinglong-termvaluechallengesofairandwaterquality,noise,forreuseorrelease.Theirsolutionshaveabroadforpublic,industrial,retailandresidentialfortheirclients.Theyareateamofdedicatedandvibration,enablingindustriestooptimiserangeofapplicationsovermanyminingandsectorsincludingschools,hotels,factories,environmentalprofessionals:scientists,theirperformancewhilemakingtheworldaotherheavyindustriestoresolvecomplexwaterhigh-riseapartments,carparks,publicbuildingsengineers,planners,andstrategicadvisorswhobetterplacethroughimprovedenvironmentalcontaminationissues,whileprovidingimprovedandwarehouses.placeinnovation,collaborationandout-of-the-boxperformance.IntheMiningsector,Envirosuitewaterresourceeconomicsandsustainability.thinkingatthecoreoftheirapproach.isactivelydeliveringresultsforawiderangeValuepropositionofcustomers,includingNewmont,BHP,Vale,ValuepropositionValuepropositionGlencore,AngloAmerican,Teckandothers.ELWA’stechnologyhasresultedinapproximatelyTheyhavebeensuccessfulinsupportingTreatingAcidMineDrainage(AMD)withtheOCRA70%energysavingandupto5000tonnesofFromtheearlyphasesofbuildingabusinesscasebothproductionandenvironmentalteamsbyprocessenhancesonsitereuseopportunitiescarbonsavingforsomeoftheircustomersacrossandunderstandingthefeasibilityofprojects,EMMoptimisingprocessesthathelpmeetoperationalandreducesthecostsoffurtherprocessingforvariousindustries.Consultinghelpclientsidentifyenvironmentalandenvironmentalobjectives.ultra-pureapplications.ThisboostsdownstreamandsocialconstraintsandopportunitiesaswelleconomicandenvironmentaloutcomesandPrimarySustainableMiningsub-sectorastoestablishapprovalstrategiesandpathways.Valuepropositionreducesliabilityconcerns.OftenwithinasingleTheycollaboratecloselywiththeirclients,processunitOCRAcanremovecontaminantsTheZeroCarbonMineprovidingsupportthroughouttheentireminingEnvirosuite’sworld-leadingend-to-endsolutionssuchasmetals,organics(biological&chemical)process,frominitialexplorationandfeasibilityarebuiltaroundthepowerofprediction,withandothersuspendedsolidsaswellasbalancingstudiestodevelopingclosureplansthataccounthyperlocalmeteorologicalforecasting,proprietaryacidityoralkalinitytoneutral.OCRAreducesfortherisingdemandfromlocalcommunitiesalgorithms,real-timedataandactionablereagentconsumptionby75%,incontrasttoandregulatorstocreateapositiveandenduringinsights.Theirsoftwareprovidespowerfultraditionallimeadditionmethods.Inaddition,thelegacyaftertheminehasceasedoperations.capabilitiesthatenablecustomerstomakefastOCRAprocesscanrecovereconomicquantitiesofandresponsibleoperationaldecisions.Theyaimmetals,providingadditionalresourcesandaddingPrimarySustainableMiningsub-sectortomakethecomplexeasy-to-usesothatanyonetotheeconomicsoftheoverallsite.inyourorganisationcanmaketherightdecision,TheCommunityMineattherighttimetoimproveenvironmentalandPrimarySustainableMiningsub-sectoroperationalperformance.EnvirosuitesolutionsSecondarySustainableMiningsub-sectorhelpminingoperatorstomaintainenvironmentalTheSmartWaterMinecompliance,optimiseoperationalefficiency,TheSmartWaterMinesupportTARPacrossdiverseparameters,reducesafetyrisks,anddemonstrateresponsibleoperations,therebyfosteringasociallicencetooperate.PrimarySustainableMiningsub-sectorTheSmartWaterMineSecondarySustainableMiningsub-sectorTheCommunityMine50AcceleratingSustainableMiningAcceleratingSustainableMining51FleetSpaceTechnologiesGaletechAustraliaGekkoSystemsGeofabricsAustralasiafleetspace.comgaletechgroup.comgekkos.comgeofabrics.coclarissa.campos@fleet.spaceinfo@galetechenergyservices.augekkos@gekkos.comb.lewis@geofabrics.com.auFleetSpaceTechnologiesisAustralia’sleadingGaletechAustraliaprovidesconsultancyservicesGekkoSystemsisagloballeaderinmineralGeofabricsisAustralia’sGeosyntheticsspecialist.spacecompanyconnectingthedeepEarthinrenewables,ESGreportingandcarbonprocessing,providingfullyintegratedsolutionsTheyhelpclientsdeliverandmaintaintheirtotheirconstellationofsmallsatellitestoreductionstrategiestotheactiveAustraliantominingcompaniesaroundtheworld.Overinfrastructurebyminimisingtheirriskandunlockmineralexplorationinnearreal-time.renewableandminingsectors.Withastrongthepast25years,GekkohasdevelopedstrongincreasingtheirvaluethroughtheinnovativeuseExoSpherebyFleet®isafirst-of-its-kindsystemfootholdintherenewableenergysector,Galetechcapabilitiesinthedesign,manufacturing,ofgeosyntheticproducts.thatcombinessatelliteconnectednodes,aAustraliaexcelsinESGreporting,DueDiligence,installationandcommissioningofenergyconstellationoflowearthorbitsatellitestoProjectManagement,GridAdvisory,Planning,andefficientmineralprocessingequipmentandValuepropositiondiscovercriticalresourcesatdepthmuchPermittingservices.TheirpragmaticapproachtocompleteplantsforawiderangeofmineralsfasterthantraditionalmethodsandverylowESGadvisoryandreportingempowerscompaniesincludinggold,silverandpolymetallics.TheGeofabrics’aimwithinminingistoreducecostenvironmentalimpact.toachievetheirsustainabilitygoals.companyalsoofferson-siteperformanceoftailingsdamclosures,reducemaintenanceofconsultingservicesforcustomerslookingtocivilinfrastructurethroughgeosynthetics,andValuepropositionValuepropositionoptimiseestablishedprocessplantsandachievemaximiselifeofcontainmentandliningsystemsthehighestoperationalperformance.Gekko’sthroughsite-specificperformancetestingandExoSpherebyFleet®technologydoesnotGaletechAustralia’svaluepropositionforrangeofsolutionsoffervalueforremoteandanalysis.utiliseexplosivesordynamitesforexplorationminingcustomersisrootedinacommitmenttoenvironmentallysensitiveoperationswithhighactivities,significantlyreducingtheimpactondrivingsustainabilityandESGreportingwithinenergycosts.Throughitsroleindewateringtailingssludge,theenvironment.Theirsensorslistentonoisetheindustry.Byharnessingrenewableenergysedimentandwastecanbereprocessed,reducingsourcespresentintheenvironment,removingsolutions,theyofferminingoperationstheValuepropositionminewasteeconomically.theneedfordisruptivemethodsorheavyopportunitytosignificantlyreducetheircarbonmachinerytoimagethesubsurface.Theamountfootprint.Additionally,theirintegratedapproachInnovativemodulardesigns,elegantsystemsandPrimarySustainableMiningsub-sectorofdrillingisalsosignificantlyreducedasaresultnotonlycontributestoenvironmentalgoalssmartmanufacturingpositionsGekkoasaworldoftheaccurate3Dmodelthatallowstofocusbutalsoleadstotangiblegoalsinoperationaltechnicalleaderingoldprocessingandlow-energyTheWasteFreeMineinareasofinterestandreducingtheneedforperformance.GaletechAustraliaunderstandsminingsolutionswithasmallfootprint.extensivedrillingandexcavation,makingminingtheimportanceofROIfortheirclients,andtheirpracticesmoreenvironmentallyfriendly.IntermssolutionsaredesignedtodelivercompellingPrimarySustainableMiningsub-sectorofproductivity,the3DsubsurfacemodelsareROI,aligningfinancialsuccesswithsustainablegeneratedinamatterof5days,upto100xfasterpracticesandESGobjectives.TheSmallFootprintMinethantraditionalmethods.PrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorTheZeroCarbonMineTheZeroCarbonMineTheSmallFootprintMine52AcceleratingSustainableMiningAcceleratingSustainableMining53GeoMobyGHDGlencoreTechnologyGloboHydroPowergeomoby.comghd.comglencoretechnology.comglobohydropower.commath@geomoby.comrohan.watts@ghd.commike.hourn@glencore.com.auinfo@globohydropower.comGeoMobyusesgeofencingandBLEtechnologiesGHDisaglobalprofessionalservicescompanyGlencoreTechnologyisanAustralianbasedglobalGloboHydrogenPower™(GHP™)isanindustry-tobringsafetyandefficiencytotheworkplace.thatleadsthroughengineeringandarchitecturalsupplierofworldclasstechnologyinthemineralsleadingfuelenhancementsystemwhichisIthasaparticularfocusonenvironmentsskillsandexperience.Theirforward-looking,processingandmetalsrefiningpartsofthemininginstalledintotrucks,busesandpowergeneratorsexposedorsubjecttodangeroussituations,innovativeapproachesconnectandsustainvaluechain.Theyarefocussedonbringingthetoupgradetraditionalpetrolanddieselenginessuchasremotesiteswithlowconnectivity,andcommunitiesaroundtheworld.Deliveringsafestandmostefficientprocessingtechnologyintocost-saving,emissions-reducing,hydrogenunderground.WithacommittedfocusonR&Dextraordinarysocialandeconomicoutcomes,totheirclientpartnerships,tohelpthemsolvethehybridengines.overthelast10years,GeoMobynowoffersatheyarefocusedonbuildinglastingrelationshipscomplexproblemsfacedinmodernmining.uniquetechnologythatenablescompaniestowiththeirpartnersandclients.EstablishedinValuepropositionvisualisepeopleandassetsinreal-timeincomplex1928,GHDremainswhollyownedbytheirpeople.Valuepropositionenvironments.Theircarrier-agnosticplatformTheyare10,000+diverseandskilledindividualsTheGHP™processhelpsfuelburnmoreefficientlyallowscompaniestovisualisetheirpeopleandconnectedbyover200offices,acrossfiveGlencoreTechnology’sJamesonConcentratorduringthecombustionprocessofaninternalassetswithhigh-precisiondetectionwithancontinents–Asia,Australia,Europe,Northandtechnologyreducesthefootprintandheightcombustionengine,whichgenerallyoperatesaccuracyofafewmeters.GeoMoby’ssolutionsSouthAmerica,andthePacificregion.ofaflotationconcentratorbyover50%,withat52–58%burnefficiency.Withinternalfunctionseamlesslyinoutdoors,indoors,andcommensuratesavingsininputmaterialscombustionalone,42–48%offuelisleftunburntundergroundenvironments.Valuepropositionandcarbonfootprint.Thisgroundbreakingfollowingcombustionproceedings,whichistechnologyalsouseslessthanhalfthepowerofareleasedintotheatmosphereaspollutionthroughValuepropositionGHDunderstandsboththebusinessandtechnicalconventionalconcentrator,furtherreducingtheanengineexhaustsystem.issuesinvolvedindeliveringoptimumminingoperationscarbonfootprint.Worldfirst,patented,underground,real-timeprojectoutcomes.Theyconsiderthegeological,Upgradingatraditionalengineintoahydrogenlocationandcommunicationsystem,usinggeotechnical,mineplanning,plantselection,TheirIsaCycleE-Wastetechnologyallowsthehybridengineallowsfossilfuelandhydrogentoportableandre-deployablebattery-poweredmineinfrastructure,tailings,environmentalefficientprocessingofelectronicwastewithoutjointlyrunanengine.FuelsavingsandnegativenodesandBLEtechnologythatisfasttodeploy,management,operationalrequirementsandthecomplexsortingtechnologiesthathindergreenhousegasemissionsreductionarerealisedscalableandcosteffectivewithprovenROIfinancialaspectsofminingtoaddressthemanyothertechnologies.TheIsaCyclesubmergedlanceasthemoreexpensivepetrolordieselisreplacedwithin12months.Costpermeterischeaperthanconflictingobjectivesinminedevelopment.Theyfurnacecanco-processabroadrangeofotherwithcheaperhydrogen.Hydrogenutilisedinaallcomparableoptions,howeverthepatentedprovidestrategicadviceaimedatmaintainingwastes,suchasmunicipalwastes,alongwithgaseousstateeasilyentersintotheairintakesolutionhasnodirectcompetition.effectiveoperationsacrosstheminelifecycle,E-Scrap,providingauniquebenefittoclientsandofanenginewithouttheneedtochangeenginefromresourceidentificationtositerehabilitationthecommunitiesinwhichtheyoperate.sensorstoaccepthydrogen.EnginesensorsPrimarySustainableMiningsub-sectortodecarbonisationstrategies.accepthydrogengasashydrogenisanalreadyPrimarySustainableMiningsub-sectorpresentchemicalwithinfossilfuel“HydroCarbonTheSmallFootprintMinePrimarySustainableMiningsub-sectorFuel”.TheSmallFootprintMineSecondarySustainableMiningsub-sectorTheZeroCarbonMinePrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorTheCommunityMineTheZeroCarbonMineTheWasteFreeMineSecondarySustainableMiningsub-sectorTheSmallFootprintMine54AcceleratingSustainableMiningAcceleratingSustainableMining55GreenEcoTechnologiesGreenGravityHansonAustraliaHydroAustraliagreenecotec.comgreengravity.comhanson.com.auhydroaustralia.com.auhello@greenecotec.cominfo@greengravity.comrachel.McSkimming@hanson.com.ausales@hydroaustralia.com.auGreenEcoTechnologies’WasteMasterisanGreenGravityisaninnovative,AustralianHansonisaleaderinbuildingandconstructionHydroAustraliaisanengineeringcompanyAustralianownedandmadetechnologythatbased,cleantechnologiescompanyfocusedonmaterialswithanextensiveproductionandservicecentreinHydro’sworldwidepumpserviceconvertsputresciblewastetoaconcentratedrepurposinglegacyminesintoenergystoragelogisticsnetworkacrossAustralia.Hansonispartorganisation,whichservicesallpumpbrands.residuewithin24hrs.Independenttestinghashubs.GreenGravityhasdevelopedatechnologyoftheHeidelbergMaterialsGroup,whichhasHydroprovidesqualityengineering,pumpshownthattheirresiduedestroyspathogensandthatutilisesheavyobjectsmovingverticallyover51,000employeesatalmost3,000sitesrebuildingandon-sitefieldservicestousersinbacteriasuchasEColi,SalmonellaandListeriathroughlegacymineshaftstoexchangeelectricalinover50countries.HeidelbergMaterialsisaAustralia,NewZealand,Vietnam,andSouth-withvirtuallynoodouranddoesnotattractandgravitationalpotentialenergy.frontrunnerontheroadtocarbonneutralityandEastAsia.Hydroservicesclientsfromarangerodents.Theresiduecansafelybehandled,circulareconomyinthebuildingmaterialsindustry,ofsectors,includingMining,Oil&Gas,Defence,transported,storedandusedviaananaerobicValuepropositionworkingonintelligentandsustainablebuildingPower&Utilities,CouncilsandAgriculture.digestersystemwhichproducesbiomethane.Thismaterialsaswellassolutionsforthefuture.in-turnisusedtogeneraterenewableelectricityGreenGravity’senergystoragetechnologyValuepropositionorasanadditivetocreateahighqualityfertiliserrepurposesredundantassetsanddisusedmineValuepropositionandcompostthroughpartners.shafts,offeringacost-effective,environmentallyHydro’sfocusisonreducingtheclient’senergysustainablesolutionforthetransitiontoHansonsuppliesacomprehensiverangeofhigh-costswhilstimprovingpumpefficiency,andtoValuepropositionrenewablesandimprovedmineclosureprospects.qualityconcrete,aggregatesandsand,andalsoachievethisgoal,HydroAustraliaoffersWirelessUsingprovenmechanicalcomponents,itproducesroadbase,asphaltandsustainableConditionMonitoringonpumpsandlaserscanUtilisingaWasteMastertorecyclefoodandensureslong-lifeperformancewithnochemicalandrecycledconstructionmaterialsforcivilreverseengineering.putresciblewasteatminingcampscannotonlyprocessingordegradation.Verticalweightconstructionandinfrastructureprojects.significantlyreducetheenvironmentalfootprintmovementprovideshighRoundTripEfficiency,PrimarySustainableMiningsub-sectoroffoodwastebutwillrecognisedoubledigitwhilerepurposingexistingstructuresalignswithHeidelbergMaterialshascommittedto:percentagereductionincosts.Forexample,circulareconomyprinciples.ThemodulardesignTheSmartWaterMineacurrentcustomerwithaveryremotesitefitsvariouslocations,withmid-sizedshafts•Generate50%ofrevenuefromsustainableproducesapprox.2,000kgoffoodwasteperday.providing5MW/25MWhcapacity,extendableproductsby2030.ByinstallingWasteMaster’son-sitetorecycleto60-100+MWhindeepshafts.Competitivefoodwaste,insteadoftransportingithundredsofcostsanda50-yearinfrastructurelifespanmake•ReduceeCO2emissionsto400kgCO2₂/tCEMkilometrestoalandfillsite,theyhavereducedtheittransformationalforgridstability,reducedby2030.costofthiswasteby40+%andreducedtheCO2etransmissioncosts,andemissionsreduction,emissionsfromtheirfoodwasteby84%,whichinsupportingrenewablesandlocalcommunityTheHansonAustraliabusinessisworkingtomeetthiscaseequatestomorethan1500tonnesperenergyinitiatives.thesetargetsby2030.annumofGreenHouseGases.PrimarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorTheZeroCarbonMineTheWasteFreeMineTheWasteFreeMineSecondarySustainableMiningsub-sectorTheZeroCarbonMine56AcceleratingSustainableMiningAcceleratingSustainableMining57K2flyKiTechHydrogenSystemsLightningProtectionInternationalLiquidIntegritySystemsk2fly.comkihydrogen.comlpi.com.auliquidintegritysystems.com.auinfo@k2fly.comKarun@kihydrogen.cominfo@lpi.com.auteal.watkins@liquidintegritysystems.com.auK2flycreatesvalueforresourcescompaniesandKiTechisaclean-techcompanythatusesLPIisafullyAustralian-owneddesigner,LiquidIntegritySystems(LIS)providesleaktheirstakeholdersinanincreasinglytransparentitspatentedtechnologytomanufacturemanufacturerandsupplierofinnovativesolutionsdetection,3Dseepagemodelling,andhigh-world.Theirsoftwaredeliversresultstoassesselectrolysed-basedhydrogensystemsdesignedintheareasofdirectstrikelightningprotection,resolutionbathymetrywithunparalleledandmanagecorporateESGrisksgloballyfromforautomotive&industrialapplications.KiTechsurgeandtransientprotection,andearthingcapabilities.operationaltoexecutivelevel,readyfordisclosurehydrogensystems,whenusedwithICengines,andbonding.Theyhaveextensiveexperiencetoallstakeholders.helpachieveupto50%fuelsavingsandupto70%inhandlingprojectsinthemostlightningproneTheircustomhardware,software,andspecialisedreductioningreenhouseemissions.areasoftheworldacrossallindustrysectors,geophysicaltechniquesensurethateachsurveyisValuepropositionincludingmining.LPIalsooffersafullsuiteofoptimisedformaximumsensitivityandaccuracy.ValuepropositionprofessionalconsultancyservicesinlightningOurnon-intrusiveapproachallowssurveystok2fly’ssolutionsimprovegovernanceacrossprotectionandearthing,andhascontributedbeperformedatanytimewithoutinterruptingnaturalandmineralresources,proventoKiTech’selectrolysed-basedhydrogensystemcuttingedgesolutionstoAustralianandoverseasoperations.automateotherwisemanualprocessestoincreasetechnologycanreducecarbonfootprintbyuptominingindustries.processefficiencybyasmuchas5-10%,which70%,reducefuel-consumptionbyupto45%,earnValuepropositioncanrepresenttensofmillionspermineinsavingscarboncreditsthatcanbetradedfordollars,andValuepropositionandincreasedrevenues.TheirsolutionsarenotcanachieveROIwithin12months.EachsurveyiscustomisedtothesiteandisonlyrequiredtoensureclientsaredisclosingComparisonbetweentraditionallightningdeployedfordifferentreasons.LISsurveysofferaccurateinformationtotheirstakeholdersbutPrimarySustainableMiningsub-sectorprotectionsystems(LPS)andLPI’sadvancedunparalleledleakdetectionservices,equippedforalsooptimisethecomplexitiesofthereportingLPSintermsoftheircarbonfootprintrevealsLPIvariousenvironmentsincludingacidic,briny,andprocess.TheZeroCarbonMineadvancedsystemshavethreetimeslesscarbonsludge-filledareasthataretoochallengingforfootprintthantraditionalsystems.Alongwithconventionalleakdetectionmethods.LeveragingResourceGovernanceprovidesassurancethatsavingsoninstallationscosts,thistechnologycustomhardware,theyguaranteenodamagetoamineralresourceprojectwillmeetstakeholdermakesasignificantcontributiontofinancialandgeosyntheticlinersandnoneedtoemptystorageandbroadersocietyexpectationsforstewardshipenvironmentalefficiencies.facilities.Specialisinginreal-timedatacollectionandmanagementofnaturalresources.andprecisegeoreferencingthroughRTKGPS,PrimarySustainableMiningsub-sectortheyefficientlyidentifyleaksignaturesandPrimarySustainableMiningsub-sectorprovidedailyupdatesanddetailedresultswithinaTheSmallFootprintMineweek.Prioritisingsafety,theyutiliselowvoltagesTheCommunityMineandremoteequipmentdeployment,requiringnoSecondarySustainableMiningsub-sectorpersonneltoenterhazardousareas,abidingbySecondarySustainableMiningsub-sectorASTMD8265standards.FollowingtheresultsTheZeroCarbonMineoftheirsurveys,LIScanleveragetheirindustryTheWasteFreeMinenetworkstoassistinresolvinganyuncoveredchallengeseffectively,facilitatingoptimalsitemanagement.PrimarySustainableMiningsub-sectorTheSmartWaterMine58AcceleratingSustainableMiningAcceleratingSustainableMining59MagnumAustraliaMineralTechnologiesMinnovareMX3Diagnosticsmagnumaustralia.commineraltechnologies.comminnovare.commx3diagnostics.comsales@magnumaustralia.cominfo@mineraltechnologies.commarketing@minnovare.comsupport@mx3diagnostics.comInnovative50yearAustraliansupplier,designerWorkingwithcustomersinminingoperationsMinnovareisanadvancedtechnologycompanyMX3DiagnosticsisaMelbourne-basedhealthandmanufacturerofspecialistwatersprayingforover80years,MineralTechnologiesdeliversthatspecialisesinimprovingtheaccuracy,technologycompanythatspecialisesinnon-andpumpingequipmenttominingthatisspecificinnovative,costeffectiveprocesssolutionsreliability,andprofitabilityofundergroundhard-invasivepoint-of-carediagnostics.MX3’stocontrollingdust,assistingwashdownofforIronOre,MineralSands,SilicaSands,Coal,rockdrillingoperations.Theiradvanceddrillcustomersincludemining,construction,pro-equipmentandproductionareas,plusaidingChromite,Gold,Tin,Tungsten,Tantalumandalignmenthardwareanddata-capturesoftwaresports,emergencyservices,andmilitarywithfirepreventionandmanagement.Magnumawiderangeofotherfinemineralsworldwide.combinestodeliverclients’drill-datafasterandgroupswhousetheiruniquesaliva-basedAustralia’sproductsincludefullautomationtoWithteamslocatedinNorthandSouthAmerica,moreaccuratelythaneverbefore.Thisenableshydrationassessmenttechnologytoenhancebluetoothandgroundspeedcontrolsystems,Brazil,India,SouthAfricaandAustralia,thefaster,smarteroperationaldecisionmaking.Intheirperformanceandsafeguardagainstcustomisedattachments,trackedrobotsandfullcompanysuppliesawiderangeofservicesandJanuary2022,MinnovarejoinedtheHexagonadverseevents.systemsintegrationtoalmostallminingvehicles.equipmentfrommetallurgicaltestingandprocessgroup-agloballeaderindigitalrealitysolutions,Applicationsincludesurface,underground,flowsheetdesign,throughtoplantandequipmentcombiningsensor,software,andautonomousValuepropositionhardrockorcoalmining,withproductssoldanddesign,manufactureandsupply,processaudits,technologiesforasimple,yetpowerfulpurpose:supportedinover65countries.optimisationandplantdelivery.PuttingdatatoworktoempoweranautonomousMorefrequentandindividualisedhydrationfuture.AspartofHexagon’sMiningDivision,assessment,madepossiblewithrapidsaliva-ValuepropositionValuepropositionMinnovarecontinuestoprovideinnovativeandbasedtesting,canimproveworkplacesafetyworld-classdrillingtechnologysolutionstoclientsandproductivity.AutomatedloggingofMX3IncreasedproductandoperationalefficienciesAllMineralTechnologiessolutionsarefocusedonacrosstheglobe.measurementdatathroughtheMX3Appandbyupto50%anddemonstratingareductionofaddingvalue.Examplesinclude:Portalallowsfordatatobeeasilysummarisedcarbonandwearcostsbyupto35%.ValuepropositiontogenerateinsightsintoworkforcehydrationFlowsheetdevelopmentandproprietaryanddemonstratecompliancewithhydrationLoweroperationalpartsreplacementcosts,separationequipment-developingcircuitsThreecasestudiesshowcasethetransformativemanagementpracticestoregulators.extendedproductworkinglifeandareturnonthatmaximisegrade,recoveryandrevenueandimpactofMinnovare’ssolutiononinvestmentin18months.minimiseplantsizeandcost.miningoperations:PrimarySustainableMiningsub-sectorAwideattachmentproductselectioncustomisedEngineeringDesign-designsincludingmodularAerisResourcessawremarkableoutcomes,TheCommunityMinetosuitcustomerpreferencesusinglatestplantsthatcanbefabricatedcheaplyinaincludinga62%reductionindilution,$32millionintechnologiesforreducedstartuporchangeoverworkshopenvironment,installedquicklyandadditionalprofitfrom119previouslyuneconomicalcoststonewandexistingsystems.relocatedeasilytoextractvaluefrombothlargemines,anda12.3%reductioninCO2emissions,andsmalldeposits.equivalenttosparing6200ktofCO2emissions.PrimarySustainableMiningsub-sectorMobileMiningUnits-toreplacetruckandshovelMacmahonachievedincreasedstoppingmeters,TheSmartWaterMinefleetswithatrackmountedmining/pumpingunit,improvedaveragegradeoftonnesmined,andansignificantlyreducingtherequirementforcapital87%reductioninslashing.SecondarySustainableMiningsub-sectorequipment,haulroads,operators,dieselandmaintenance.NorthernStarexperiencedthepowerof100TheZeroCarbonMineadditionaldrillmetersperday,a17%increaseinLyonsUnits-Anew,technologybasedsurgebin/drillingproductivity,a3.5%reductioninstopeCDtank,theseunitsprovidearangeofbenefitsturnovertime,andapproximately$8.4millioninincludingfeeddeslimingandstabilisation,realadditionalrevenue.surgecapacity,stableoperationatpumpingdensitiesupto65%solidsandbeneficiationinPrimarySustainableMiningsub-sectorsomeapplications.TheZeroCarbonMinePrimarySustainableMiningsub-sectorTheSmallFootprintMine60AcceleratingSustainableMiningAcceleratingSustainableMining61OffWorldAustraliaOLEOLOGYOptrixOwenCustomProductsoffworld.aioleology.com.auoptrix.com.auowencustomproducts.com.auinfo@offworld.aisales@oleology.com.aujwatts@optrix.com.aukaryn.owen@owencustomproducts.com.auOffWorldisaprivatecompanythatdesigns,OLEOLOGYisanAustralianwastewaterOptrixisanAustraliantechnologycompanyOwenCustomProductsdesignsanddevelops,andmanufacturesAI-poweredroboticengineeringtechnology,treatmentandprocessingthatcreatesinnovativedataintegrationandmanufacturescustomSwingPedalsystemsplatforms.OffWorldisreinventingthemining,companybasedinPerth.Ithasatrackrecordvisualisationsoftwarevaluedbymining,heavypredominantlyfordraglinesbothinAustraliaandmanufacturing,andconstructionindustriesbyofover20yearsofwatertreatmenttoremoveindustry,infrastructure,andenergymarkets.internationally.ThesesystemscanberetrofitteddevelopinganewgenerationofrobotspeciesthatcontaminantsandpollutantstoregulatoryandBybringingtogetherdatafrommanydifferenttoexistingdraglinesorsuppliedasoriginalworktogetherintelligentlyinaswarmcapabilitybestenvironmentalpracticerequirementsfromsources,thenanalysingandvisualisingthisequipmentand/orreplacement.Maintenance/toextractcriticalmineralsandmaterials.ThewastewatersourcessuchasMining,Oil&Gas,data,Optrixallowsclientstodrivetowardsrepairservicesarealsoprovided.ruggedroboticswarmscanworkefficiently,leachate,logisticalsupplybases,Marineandzerocarbonthroughenergyreductionandindependentlyandtogetherinaneco-friendlyIndustrialwastewater.OLEOLOGYclientsincludeimprovedproductivity.Valuepropositionapproachinextremeconditions–allwhileChevron,BHP,RioTinto,Toll,Defence,Westrac,removinghumansfromharm’sway.CumminsandAustralianAntarcticDivision.ValuepropositionImprovementindraglineproductivitywillrealiseanimmediatereductionincostsandenvironmentalValuepropositionValuepropositionManyminingcompanieshavegonedownadigitalimpact.Improvedswingpedalsystemsdesignedpath,butstilldonothavea‘singlesourceofthebyOwenCustomProductsnegatetheneedThebenefitsinclude:OLEOLOGYhasbeenabletoreducewatertruth’thatpresentsalloftheirdigitalinformationtoshutdowndraglineseveryfewweekstousageonsiteforoperationsandnon-processinginoneplace.ARDI,Optrix’sdataintegrationrecalibrate,resultingin:•Unlockingstrandedanddormantminesinfrastructure,withsomesitesachievinguptoplatform,allowsclientstogetafulldigitalviewthroughprecisionmining,minimaldilutionand50%reductioninusage.Furtherreductionsinoftheirdata.Itbringsalldatatogether,where•Anestimateddraglineproductivitywastemovement.carbonfootprintarepossiblebyremovingthestakeholdersfromthefieldtotheboardroomimprovementofapproximately4%,savingtherelianceonReverseOsmosisorchemicaldosingbycanuseittocreatevalueandinsights,drivingatypicalAustraliancoalmineAUD3millionper•SubstantialEconomicValueCreationvialowerretrofitorreplacementwithamodularOLEOLOGYrangeofimprovements,includingtowardsnetyear;andCapexandscalableOpex.treatmentsystem.Eachsolution,whileachievingzerocarbongoals.ARDIusesAIandanalysistowatercompliancetotheenvironmentalregulator,identifyenergysavingsbyinterrogatingenergy•Improvedenvironmentalimpactthrough•Significantminedeploymentbenefitssuchashasalsoimprovedmaintenanceandpersonnelusedata.Itcombinesenergydatawithotherlesstransport,wastematerialsand26%revenueandreducing18%operatingcost.timeonsite.OLEOLOGYhasprovenbenefitsproductionandmaintenancesystems,modelstheemissionsassociatedwithshutdowntoreducepowerconsumption;reducetruckingintroductionofrenewableenergysources,andmaintenanceactivities.•Removingworkersoutofharm’swaybyfullycosts,reducewaste,removeunnecessarytracksenergyusageovertimeasclientsmovetooperationalautonomy.personnelonsiteandreduceenvironmentalrisknetzero.PrimarySustainableMiningsub-sectorwhilecreatingreusebenefits.•Enablingzeroentrymining.PrimarySustainableMiningsub-sectorTheSmallFootprintMinePrimarySustainableMiningsub-sector•AcceleratingtransitiontonetzerothroughTheZeroCarbonMineelectricequipmentandeliminatingtheneedforTheSmartWaterMineenergy-intensiveconventionalmachinery.PrimarySustainableMiningsub-sectorTheSmallFootprintMine62AcceleratingSustainableMiningAcceleratingSustainableMining63ParvateESGPeatsGroupPhibionPitcrewAIparvateesg.com.aupeatssoil.com.auphibion.compitcrew.aiinfo@parvateesg.com.auadmin@peatssoil.com.auinfo@phibion.cominfo@pitcrew.aiParvateESGisaforward-thinkingESGUtilisingtheirrenownedBiobiNtechnologyPhibionisawhollyownedAustralianCompanyPitcrewAIwasbornoutofaninquisitive,engaged(Environmental,Social,andGovernance)alongsidevariousothereffectivecollectionwithitsheadofficeinBrisbane,Queensland.Theygrouptryingtohelpcustomerssucceed.TheyconsultancybasedinPerth,WesternAustralia.strategies,PeatsGrouphasrevolutionisedorganicprovidesaferandmoresustainabletailingsandareexpertsinengineering,specificallycomputerCommittedtoadvancingAustraliansustainabilitywastecollectionandon-siteprocessingfacilitiesthisisdonebyin-situdewateringofthetailingvisionandradiometricinspection.PitcrewAIisinitiatives,theirexperiencedteamcollaboratesonaglobalscale.Theyarecommittedtofosteringstoragefacility.PhibionhasapatentedprocessshapingthefutureofminingandtransportbywithdiverseclientstonavigatetheintricateESGasustainablefuturethroughinnovativeandeco-calledAcceleratedMechanicalConsolidationenablingautonomousvehicleinspectionsandlandscape.Theyspecialiseintailoredstrategies,friendlywastemanagementsolutions,making(AMC)andusestheMudMastermachinetoassistprognosticswithreal-timeconditionmonitoring.regulatorycomplianceandproactivesupport,asubstantialpositiveimpactonthecommunitythisprocess.Theirautomated,AIandthermographybasedcontributingtosustainablegrowthacrossvariousandtheenvironment.PeatsGroupproudlyassessmentsinspectionsystemenhancessafety,industries,includingminingandMETS.ParvateservesastheprimaryprocessorofmetropolitanValuepropositionefficiency,andsustainability,whileenrichingESGproudlyrepresentsAustralianexpertiseinAdelaide’sgreenandfoodorganics,sourcedhumanlives.fosteringsustainabilityglobally,withagrowingthroughacomprehensivenetworkencompassing•Increasesdensityofthetailingsbyupto20%presenceinIndiaandSingapore.councilkerbsideandbusinesscollections,as•Increaseswaterrecoveryby40%Valuepropositionwellaspartnershipswithhotels,supermarkets,•Reducestailingdamvolumeby50%Valuepropositionschools,officebuildings,foodprocessors,and•Increasesstrengthto35kPaPitcrewAIenablescostsavingsthroughearlymanufacturers.•DefersornegatescapitalexpenditurebyidentificationoftyreinjuryordamageandParvateESGspecialisesinempoweringincreasestyrerepairratesratherthandisposal.sustainablegrowthwithintheminingandValuepropositionreducingfuturewallraisesandextendingtheTheyincreaseproductivitythroughtrucksMETSsectors.Withadeepunderstandingoflifeofthetailingsstoragefacility(TSF)havingmoreavailabilityanduptime,tyresindustryintricacies,theydevelopcustomisedPeatsGroupistheproudinnovatorbehindthe•Reducestheneedforadditionalnewdamsandstayingoperationallonger,forecastingdamageESGstrategiesthatseamlesslyintegratewithBiobiNwastemanagementsystem.Theyempowersavesvaluablegreenspaceprogressionandoptimisingplanningfortyreoperations,enablingregulatorycompliancebusinessesalloverAustralia,includingthoseinservice.Fromasustainabilityperspective,Pitcrewandenhancingcompetitiveadvantage.Theirremoteminingareas,toself-managetheirfoodPrimarySustainableMiningsub-sectorAIalsohelpstodecreasetyrewastage.focusisonformingsustainablepartnerships,wasteandcompostablematerialsefficientlyTheWasteFreeMineimprovingbusinessperformance,anddeliveringon-site,eliminatingthehassleandcostsofPrimarySustainableMiningsub-sectorclear,actionableoutcomes.Theybelieveinoff-sitewastetransportationandprovidinganSecondarySustainableMiningsub-sectorprovidingpracticalsolutionswithoutunnecessaryenvironmentallyfriendlyfertiliserforuseinmineTheSmartWaterMineTheWasteFreeMinecomplexity,allowingclientstoconcentrateonrehabilitationorlocalcommunityprojects.theircorebusiness.ParvateESG’sproactiveguidanceandexpertisehelpsnavigatethePrimarySustainableMiningsub-sectorevolvingESGlandscapeandsecureasustainablefutureforminingandMETS.TheWasteFreeMinePrimarySustainableMiningsub-sectorTheCommunityMine64AcceleratingSustainableMiningAcceleratingSustainableMining65PX4SoftwareRealTimeInstruments(RTIAustralia)RemBindRWDIpx4software.comrealtimeinstruments.comrembind.comrwdi.comtoby.carrigan@px4software.comsales@rtiaustralia.cominfo@rembind.comsolutions@rwdi.comPX4istheonlytrulyjurisdictionallyspecificInaworldwherereal-timedecision-makingRemBinddevelopsremediationsolutionsforRWDIisaClimateandPerformanceEngineeringtenementmanagementsoftware,allowingiscrucial,RTI–RealTimeInstrumentsiscontaminatedsoil.RemBind’scornerstoneconsultancyfirmwithateamofover800companiestodemonstratetheircompliancerevolutionisingbulkmaterialhandlingwithpowderedproductsbindupandneutraliseengineers,scientistsandspecialists.Theiragainststatutoryobligations.Thiscloud-basedcutting-edgeon-linemeasurementandanalysisenvironmentalcontaminantsinsoil,withakeyglobalanddeeptechnicalexpertisehelpsclientsandintuitivesystemalsotracksallagreementscanners.SinceitsinceptionasaninstrumentsfocusontoxicPFASchemicalsthatoriginateovercomedesignandoperationalchallengesobligationsandevidenceofcompliance,serviceprovidertotheAustraliancoalindustryfromfire-fightingfoams,labelledthe‘forevertoenablethemtomeetambitiousgoalsstakeholdercommunicationsandsecondaryin2004,RTIhasgrownanddiversifiedintoachemicals’becauseoftheirpersistenceinthewhilemaintainingtheproject’sharmonywithpermits/licencesrequiredforoperation.PX4isgloballeader,manufacturingandsupplyingon-environment.RemBindproductshavebeenusedthenaturalenvironment.RWDI’sexpertisethesinglesourceoftruthfortenementsandalllineelementalandmoistureanalysisscannerstotreatthousandsoftonnesofcontaminatedsoilintheminingsectorincludesclimateandassociatedrequirements.totheglobalmining,mineralprocessing,poweracrossNorthAmerica,Europe,Australia,andNewmeteorology,noiseandvibration,dustandairgeneration,steel,cementproductionandfoodZealand.RemBindworkswithawidevarietyofquality,greenhousegas,windengineeringandValuepropositionindustries.civilandminingcontractorsworldwidetoaccessresiliencyduringplanningandoperationalphasesthemostsuitablesoilmixingtechnologiesandoftheproject.ThisexpertiseissupportedPX4improvesefficiencyoftenementandapprovalValuepropositionwillworkalongsideminingcontractorstoofferathroughdetailedmodelling,monitoringandmanagementbyupto40%,withaccessible,rangeoftreatmentsolutionsforcontaminatedproprietysoftware.visibleandauditabledata.PX4isagovernanceRTItechnologyaddressesacriticalchallengesoilsallowingsafeonsitereuseoroffsitedisposaltoolthatstreamlinesapprovalmanagement,encounteredbybulkmaterialhandlingoperationsoftreatedsoils.Valuepropositionwithjurisdictionally-specificworkflowsprovidingacrossvariousindustries,enablingoperationstoRWDIisaclimateandperformanceengineeringbettergovernanceandcertaintyofongoingmakeinformeddecisionsinrealtime,resultinginValuepropositionconsultancyfirmsupportingminingoperatorscompliance.PX4’sStakeholderCommunicationsimprovedrecovery,reducedwaste,andenhancedduringplanningandoperations.RWDI’sandAgreementsModulesallowforbettercaptureoperationalcontrol.Throughtheirindustry-ACircularEconomyapproachencouragesservicesincludemodellingandmonitoringofofcommunityandstakeholderconsultations.leadinganalytics,RTI’scustomersconsistentlythereuseandregenerationofmaterialsornoise,vibrationandblasting,airquality,dustThroughprovidingbettervisibilityofobligationsexceedrevenue,yieldandproductiontargetsproducts,especiallyasameansofcontinuingandgreenhousegas(GHG)emissions;andfieldrelatingtolandaccess,nativetitleagreementswhilesimultaneouslydecreasingtheircarbonproductioninasustainableorenvironmentallyservicessuchasthedirectionalBarnOwlnoiseandtrackingdisturbanceandrehabilitationfootprint.Theimprovedefficiencyandstricterfriendlyway.RemBind’sprojectsdemonstratemonitoringsystemandSmartaDataforremoteprogress,PX4ensuresallobligationstothequalitycontrolmeasuresenablecustomerstohowcontaminatedsoilscanbetreatedandmonitoring.RWDIhasalsodevelopedthecommunityareconsideredindecisionmakingloweremissions,therebycontributingtotheirreusedatminesitesinapracticalandsafeCALPUFF-IDM(inversedispersionmodelling)andthatallrelevantinformationiscapturedinanet-zerotargets.manner,alleviatingtheneedforunsustainableapproachtoidentifyandquantifyGHGareacentralisedsourceoftruth.andcostlyremediationoptionssuchaslandfillemissionsourcesforopen-pitminingoperationsPrimarySustainableMiningsub-sectordisposal.RemBindcandemonstratetheonsitetoenablethedevelopmentandvalidationofPrimarySustainableMiningsub-sectorimmobilisationofsoilcontaminantsfollowedsuitableabatementprograms.TheSmallFootprintMinebythesafereuseoftreatedsoilsatsiteandTheCommunityMinehowminerscanleverageconventionalminingPrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorequipmentratherthanspecialisedremediationTheZeroCarbonMineequipment.Inparticular,theonsitemanagementTheWasteFreeMineofsoilscontainingPFAScontaminantscanbeAcceleratingSustainableMining67acosteffectiveandpracticalsolutionformine66AcceleratingSustainableMiningsites.RemBindsprojectexperiencewillhelptopavethewayforthesafe,sustainableandpracticalmanagementofcontaminatedsoilsatminesites,withanemphasisonthesustainablemanagementofPFAScontaminantsinsoils.PrimarySustainableMiningsub-sectorTheWasteFreeMineSecondarySustainableMiningsub-sectorTheSmallFootprintMineScantechInternationalSedgmanSentientComputingSouthernInnovationscantech.com.ausedgman.comsencom.com.ausoutherninnovation.comh.kurth@scantech.com.aujennifer.agnew@sedgman.cominfo@sencom.com.auinfo@southerninnovation.comScanTechisaworldleaderinsupplyofSedgmanistheleadingproviderofintegratedSentientComputingisanAustraliansoftwareSouthernInnovation(‘SI’)isanadvancedrepresentative,continuous,realtimemineralsprocessingsolutions.Since1980,developmentcompanythatspecialisesinmanufacturingcompanythatdevelops,measurementtechnologiesforconveyedSedgmanhasadvancedthestandardofprovidingpowerfulandimmersivevirtualdesigns,testsanddeployssensingproductsmaterialstothemineralssector.excellenceandinnovationindesign,deliveryandenvironmentstodeliversolutions,includingDigitalforvariouscommoditiesintheminingsector.SIoperationsforclients.TheirAustralianheritageTwins,blendedtrainingpackagesandotherESGhasdevelopedworld-leadingmaterialanalysisValuepropositionhasturnedintoalegacyofprojectsaroundthecommunicationsolutions.Sentient’sDigitalTwininstrumentation,leveragingadvancedphotonworld,andtheyhaveexpandedfromtheirearlyproductInDIisaversatilevirtualinterfacethatsciencesensortechnologyandproprietaryAIDigitalisingconveyedflowshasproventoincreasedaysincoaltotoday,wheretheirexpertisecanbeprocedurallygeneratedfromengineeringdataprocessingalgorithms.SI’sexperiencedoregradeby5-20+%andremove10-20+%wasteincludesironore,preciousandbasemetals,modelsandleveragesacompany’sexistingdatamanagementteamhasadeeptechnical,scientificthroughbulkoresorting,whichcansave10-20%lithium,potash,sodaash,andindustrialminerals.sourcestoprovideascalableandfuture-proofandcommercialexpertise,extensiveindustryGHGemissionsand10-20%tailingsgeneration.ItSedgmanactivelyusesdataandknowledgesolution.Itiscurrentlyhelpinghundredsofuniquerelationshipsandatrackrecordofsuccessfullycanalsoleadtoshort(weeks)paybacksthroughgainedacrossfourdecades,hundredsofmonthlyuserstobetterservicetheirmulti-deliveringcomplextechnologydevelopmentincreasedmetalrecoveriesbyreducingprocessprocessingandmaterialshandlingprojects,andbillion-dollarassets.Softwareissupportedbyprojects.Theirprimarybusinessmodelinvolvesfeedvariability.WithScanTech,somesitesnumerouscountriestodeliverreliablesolutionstrainingpackageswhicharescaffoldedlearningcollaboratingcloselywithpartnerstocraftreducedCAPEXby10-20%inplantconstructionfortheirclients.TheyarealsoknownfortheexperiencesthatincludeinteractiveeLearningcustomisedsolutionsthatapplyadvancedthroughlowerthroughput,andutilisingproductabilitytosuccessfullytransfertechnologiesandmodules,customVRtrainingandinteractivetechnologytonoveloperationalparameters.qualitybypass.Coalplantproductqualitybypassinnovativetechniquesacrosscommodities.computer-basedtraining.SentientComputingSouthernInnovation’sproductsboastaflexiblehasa2monthpaybackinwashplantcostsavings.helpminesitepersonnel,utilityproviders,seniorarchitecture,facilitatingsmoothintegrationintoValuepropositionbusinessleadersandlocalcommunitiesupskillexistingcustomernetworks.PrimarySustainableMiningsub-sectorbothtechnicallyandprofessionally.Sedgman’svisionforasustainableworldValuepropositionTheWasteFreeMineincludesminingandmineralsprocessingdoneValuepropositiondifferently.SedgmanisengagingwithinnovativeSI’sdigitalproductsimprovethespeedandSecondarySustainableMiningsub-sectorandsystems-thinkingpartnerstoworkacrossBeingabletoshareacommon3Dmodeloffsite,accuracyoftheanalysisofminerals.Thisenablestraditionalscopeboundariestoidentifysolutionsconnectedtodata,significantlyreducestraveltothedeploymentofhigh-speed,real-timeanalysisTheZeroCarbonMinethatreduceemissions,tailingvolumes,andnetsite,negatestheneedfortrainingandmonitoringsystemsinmineralprocessingoperationsthatwaterusage.Thistransformationissupportedbyindangerousminingenvironments,increasesdramaticallyimproveprocessefficienciesandtechnicalinnovationsacrosstheindustry,fromspeedofdecisionmakingandincreasesclarityofproductyields.reducedenergycomminution,coarseflotation,informationthroughcommunicatingwithSentientSensor-basedoresortingtechnologieshaveearlywasterejectionandgradeengineering,Computingglobalexperts.beenidentifiedasawaytoincreasegradesscalablemodularsolutionsforadaptableandproductivity,andreducewaste,waterprocessing,andopportunitiesforreprocessingPrimarySustainableMiningsub-sectorconsumption,energyuseandGHGemissions.SI’sandreuseoftailings.TheycansupporttechnicaladvancedsensorsandalgorithmsremovetheevaluationofprocessingoptionsfromagreenTheCommunityMineneedforcostlysamplingandlab-basedanalysishousegasandwateruseimpactandcapitalandenablerapidandaccuratedecisionmakingandoperatingcostperspective,tosupportwhenappliedtomechanisedrealtimeoresortingbestforproject,communityandenvironmentordrilling.decisionmaking.JustoneinstallationofSI’sGradeScanunitshasdemonstratedannualvalueinuseexceeding$60PrimarySustainableMiningsub-sectormilliondollars.TheSmallFootprintMinePrimarySustainableMiningsub-sectorSecondarySustainableMiningsub-sectorTheWasteFreeMineTheSmartWaterMineSecondarySustainableMisningsub-sector68AcceleratingSustainableMiningTheSmallFootprintMineAcceleratingSustainableMining69SpaceDraftThiessRehabilitationUnderconVoconiqspacedraft.comthiessrehabilitation.comundercon.com.auvoconiq.comlucy.cooke@spacedraft.cominfo@thiessrehabilitation.comadmin@undercon.com.auinfo@voconiq.comSpaceDraftisarevolutionaryvisualThiessRehabilitationofferscomprehensiveUnderconisaspecialisedservicecompanyVoconiqisaglobaldatascienceandengagementcommunicationtool.Ittransformsconversationsminerehabilitationservicesforsitesofallsizes,providinginnovativeconcretingsolutionsforcompanypassionateaboutcommunity.Voconiq’saroundminingbysimplifyingintricateprocessescommodities,requirementsandlifecyclestages.theminingandcivilsectors.Underconaretheprovenscience-basedapproachrecordsthroughreal-timevisualmapping.DrawingDeliveredbyminers,whoarealsoenvironmentalpioneerdevelopersofthepatentedWETBAGcommunityviewsandopinionsacrosstheworld,inspirationfromstagechoreography,ithelpsexperts,theirservicesincludeprogressiveConcreteBatching&OnsiteMixingSystem.Theyprovidingcompanies,industriesandinstitutionspeopleseeavisualrepresentationofplansbeforeminerehabilitation,mineclosure,includingarecommittedtogreeninitiativesandsustainablewithvaluableinsightstoinformbusinesstheyhappen,whichenhancescollaboration,infrastructureremoval,abandonedmines,practicesandunderstandtheresponsibilitypracticesandshapedevelopmenttrajectories.optimisesresources,andstrengthenssafetyandcontaminatedlandrequirements.TheissofindustrytomovetowardscarbonfootprintThecompanyusesworld-leadingdatasciencepractices.Itsuser-friendlyinterfacereplacesRehabilitationhasindustry-leadingcapabilityinreduction.Undercontakeprideintheirworkandtechniques,aunique‘research-as-engagement’traditionalmethodswithdynamicvisuals,offeringenvironmentalandcivilengineering,landformaimtoestablishlong-lastingpartnershipstomodelofpractice,andflexibilitytosolvethedrag-and-dropsimplicityforintuitivelearningdesignoptimisation,advancedsurveying,assetprovideahealthier,greenerfuture.challengesofdiverseoperatingenvironments.onanydevice.SpaceDraftrevolutionisesvisualmanagementandmaintenance.Voconiqbelievevoicesmatterandworkstoandthoughtfulcommunication,drivingefficiencyValuepropositionincreaseunderstandingbetweenorganisationsandempoweringdiverseteamsinaswiftlyValuepropositionandthecommunitiestheyworkalongside,tobuildevolvinglandscape.Withreal-timeupdatesandTheWETBAGSystem(WBS)easesthepainoftrustandstrengthenrelationships.language-agnosticfeatures,iteffortlesslybridgesThiessRehabilitationofferscomprehensiveconcretesupplytoundergroundandremotecommunicationgapshelpingallstakeholderstorehabilitationservicesfortheminingsectorforprojects.Itcreatessignificantcostsavings,Valuepropositionsingfromthesamesongsheet.sitesofallsizes,commodities,requirementsassuresquality,reduceslogistics,andsimplifiesandlifecyclestages.Since2007theyhavetheneedforskilledlabour.TheWBSprovidesVoconiqdeliversminersstrongerandmoreValuepropositionrehabilitatedover10,215hectares.ThiesstheabilitytodesignspecificrequirementsofproductiverelationshipswithhostcommunitiesRehabilitationoffersateamwithtechnicaleachbaggedmix;theonlysiteadditiveiswater.throughprovidingcommunitymonitoringdata.SpaceDraftprovidesacompellingvalueandoperationalexpertise,backedbywholeAllowingconcreteondemand,anywhereandVoconiqtechnologyandprocessesenablethepropositionforminingcustomers:of-mine-lifeknowledge,andafullsuiteofanytime,theWETBAGmaybestoredonsiteeffectivemanagementofsocialrisk.WithReducedDowntime:A40%reductionintotalrehabilitationservices.Thisincludesprogressivereadyforuseforupto4months.ThisisaVoconiq,minerscanobtainandmaintainthesocialshutdownman-hours,savingupto$1.872millionminerehabilitation,mineclosure,includingrevolutionarygreeninitiativeandsustainableperformancerequiredwithlessresourcesbyAUDincarbonemissionvalue.infrastructureremoval,abandonedminesandpracticethatisnotundertakenforthistypeofoperatingandengagingsmarter.ReducedIncidents:Upto30%reductionincontaminatedlandrequirements.Withaccessproductanywhereelseinthemarket.Inaddition,incidents,leadingtosaferoperationsandlowertoalargeassetbaseandstrongbalancesheet,sitecostsarelowerthanaconventionalbatchingPrimarySustainableMiningsub-sectorcosts.andtheabilitytoexplorealternativecommercialplantandtheWBSiseasilytransportabletotheReductionofCarbonEmissions:2,252.8tosolutions,theyfurtherhelpclientsaccessnextproject.ThemoreremoteorinaccessibletheTheCommunityMine2,760.32metrictonnesofCO2emissionsreduced,tailoredsolutions.Clientscandrawontheirfullproject,thebetterthevalue.affirminganenvironmentallyconsciousapproach.suiteofrehabilitationrequirementsindesign,ThesequantifiedbenefitsshowcaseSpaceDraft’sdevelopmentanddelivery.AkeyfeatureistheirPrimarySustainableMiningsub-sectorcapacitytoenhanceoperationalefficiency,safety,abilitytooptimiseinputsandoutcomes,fromandenvironmentalstewardship,enablingminingrehabilitationdesignsandoperationalschedules,TheSmallFootprintMinecompaniestoexcelinasustainablemanner.toidentifyingefficiencygainsandequipmentutilisationoptions.SecondarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorPrimarySustainableMiningsub-sectorTheZeroCarbonMineTheCommunityMineTheSmallFootprintMineSecondarySustainableMiningsub-sectorTheSmallFootprintMine70AcceleratingSustainableMiningAcceleratingSustainableMining71WorldpolyXencoServicesworldpoly.comxencoservices.comrob@worldpoly.comalan.hocking@xencoservices.comAustralianownedandbased,WorldpolyleadsXencodeliversoperationalimprovementsupporttheworldinthedevelopmentandproductionoftominingbusinesses.Withdecadesoftop-tierinternationalstandardPEpipeweldingfusionexperience,theirexpertteammemberscoupleequipment.WorldpolyhaveexportedAustralian-apragmaticapproachwithprovenmethodsandengineeredbuttweldingequipmentto120practicestoimprovebusinessefficienciesandcountriesandmanufactureanindustryleadingcommercialoutcomes.Australian-madehighpressure,trackdrivenbuttweldingrangeaccordingtoISO&NorthSustainabilityservicesincludeenvironmentalAmericanstandards.consulting,closureplanning,governancesystemsandtailingsandwatermanagement.ValuepropositionValuepropositionWorldpolyhelpsminerstomovewater/slurrytootherlocationsasrequired.TheirbuttweldingEnvironmentalmanagementiscrucialtomachinesofferlowenvironmentalimpactmaintainoperationalefficiencyandcompliance.throughlessrelianceonheavytruckhaulageXenco’steamunderstandstheimportanceofforde-wateringormovingwater.HighDensityfuture-proofingyourenvironmentalstrategy.Polyethylene(HDPE)pipewhenweldedproperlybyXencounlocksprofitabilityandsustainabilityqualifiedtechnicianswilllastover100yearswhenbenefitsthroughcollaborativelysolvingminecorrectlyinstalledunderground.HDPElastsfouroperationalchallenges.timeslongerthansteelforslurrywork,andcanberepositionedrelativelyeasily.ButtweldedHDPEPrimarySustainableMiningsub-sectorismorecost-effectivethanusingelectrofusionfittingsandis100%recyclable.AttheendoftheTheWasteFreeMineprojectitcanberepurposedeitheronsiteoroff.AfullyweldedHDPEwillnotblowapartlikeaSecondarySustainableMiningsub-sectorrubberringjointedpipesystem.TheSmallFootprintMinePrimarySustainableMiningsub-sectorTheSmartWaterMineSecondarySustainableMiningsub-sectorTheWasteFreeMine72AcceleratingSustainableMiningAcceleratingSustainableMining73EmpoweringGreenAmbitionwww.austrade.gov.auwww.austmine.com.au