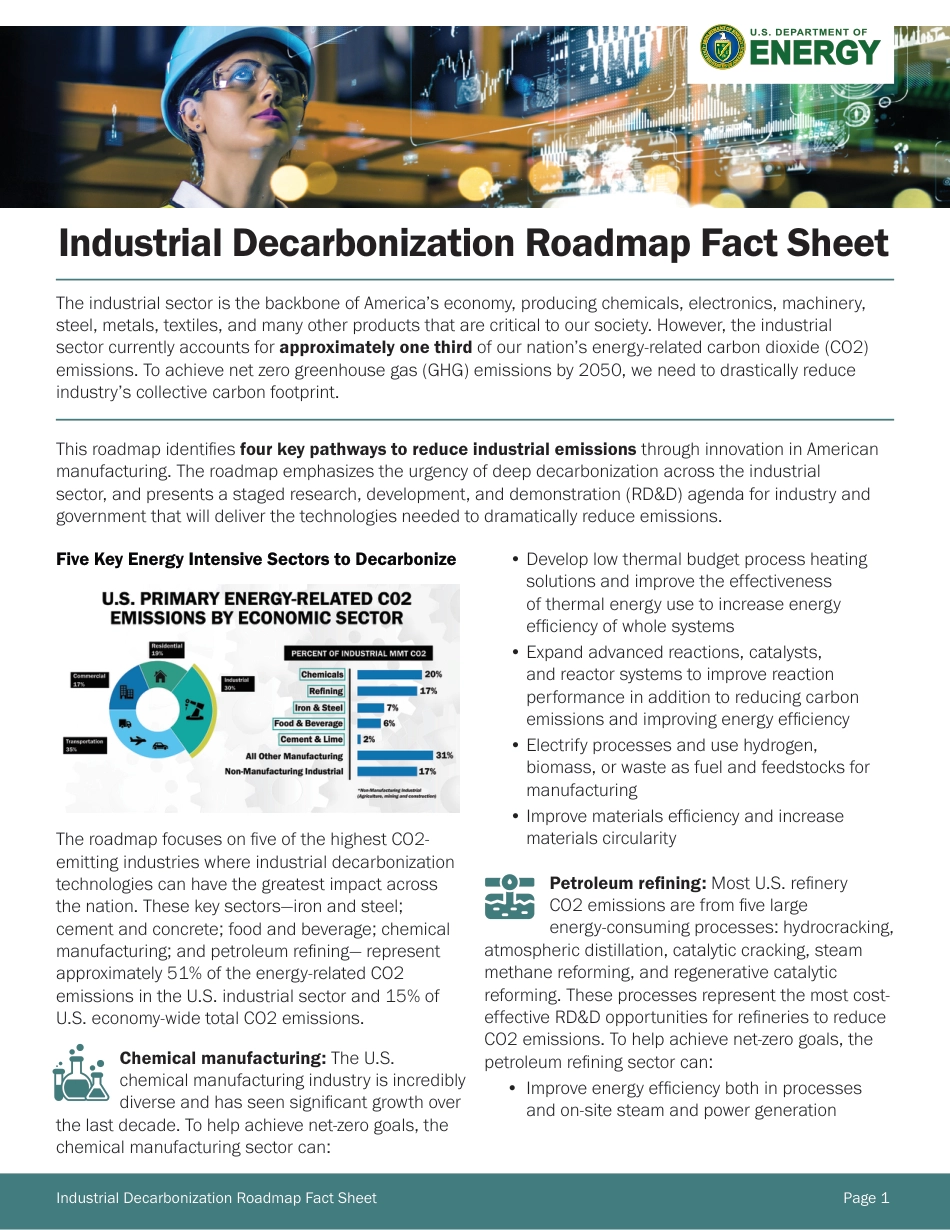

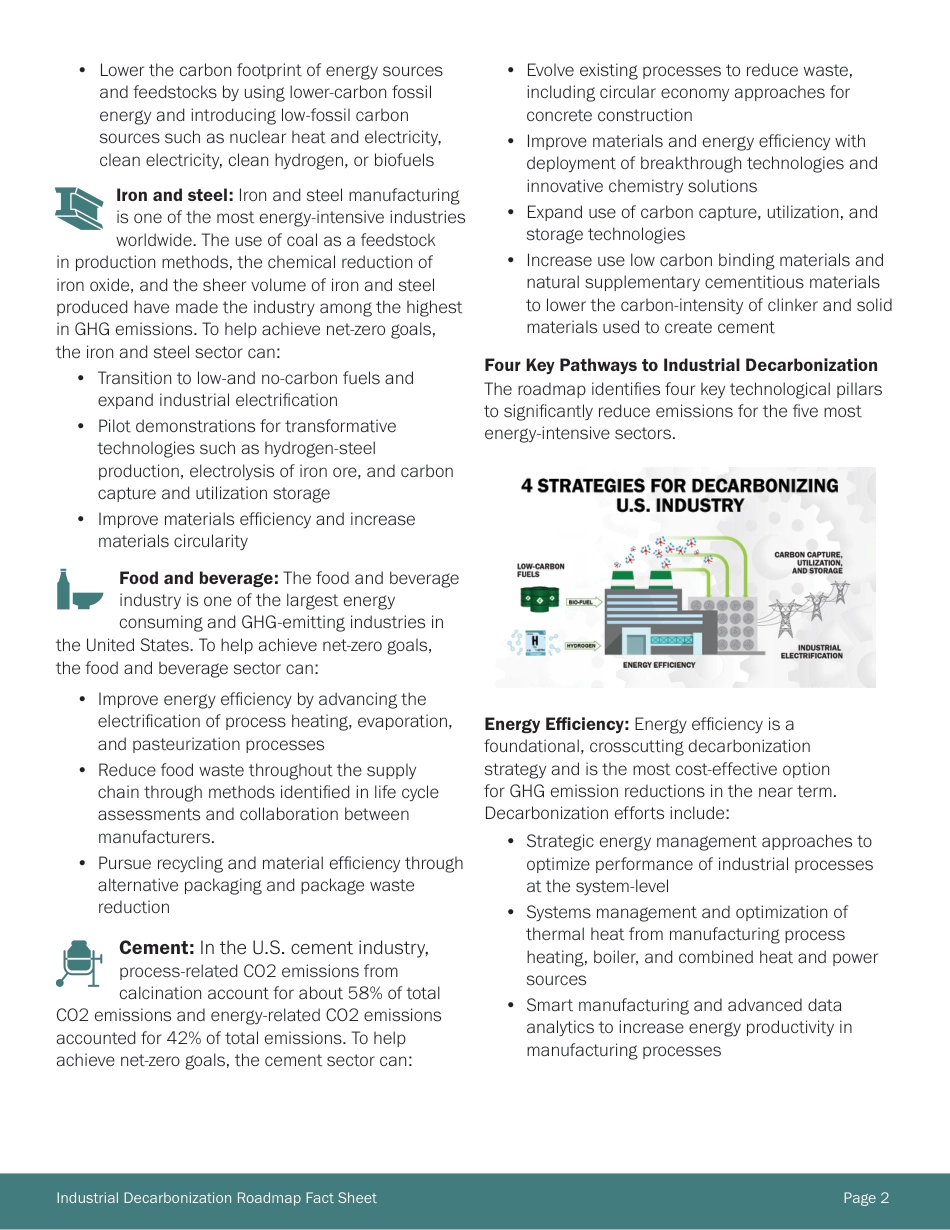

Industrial Decarbonization Roadmap Fact SheetThe industrial sector is the backbone of America’s economy, producing chemicals, electronics, machinery, steel, metals, textiles, and many other products that are critical to our society. However, the industrial sector currently accounts for approximately one third of our nation’s energy-related carbon dioxide (CO2) emissions. To achieve net zero greenhouse gas (GHG) emissions by 2050, we need to drastically reduce industry’s collective carbon footprint. This roadmap identifies four key pathways to reduce industrial emissions through innovation in American manufacturing. The roadmap emphasizes the urgency of deep decarbonization across the industrial sector, and presents a staged research, development, and demonstration (RD&D) agenda for industry and government that will deliver the technologies needed to dramatically reduce emissions.Five Key Energy Intensive Sectors to DecarbonizeThe roadmap focuses on five of the highest CO2-emitting industries where industrial decarbonization technologies can have the greatest impact across the nation. These key sectors—iron and steel; cement and concrete; food and beverage; chemical manufacturing; and petroleum refining— represent approximately 51% of the energy-related CO2 emissions in the U.S. industrial sector and 15% of U.S. economy-wide total CO2 emissions.Chemical manufacturing: The U.S. chemical manufacturing industry is incredibly diverse and has seen significant growth over the last decade. To help achieve net-zero goals, the chemical manufacturing sector can: • Develop low thermal budget process heating solutions and improve the effectiveness of thermal energy use to increase energy efficiency of whole systems• Expand advanced reacti...