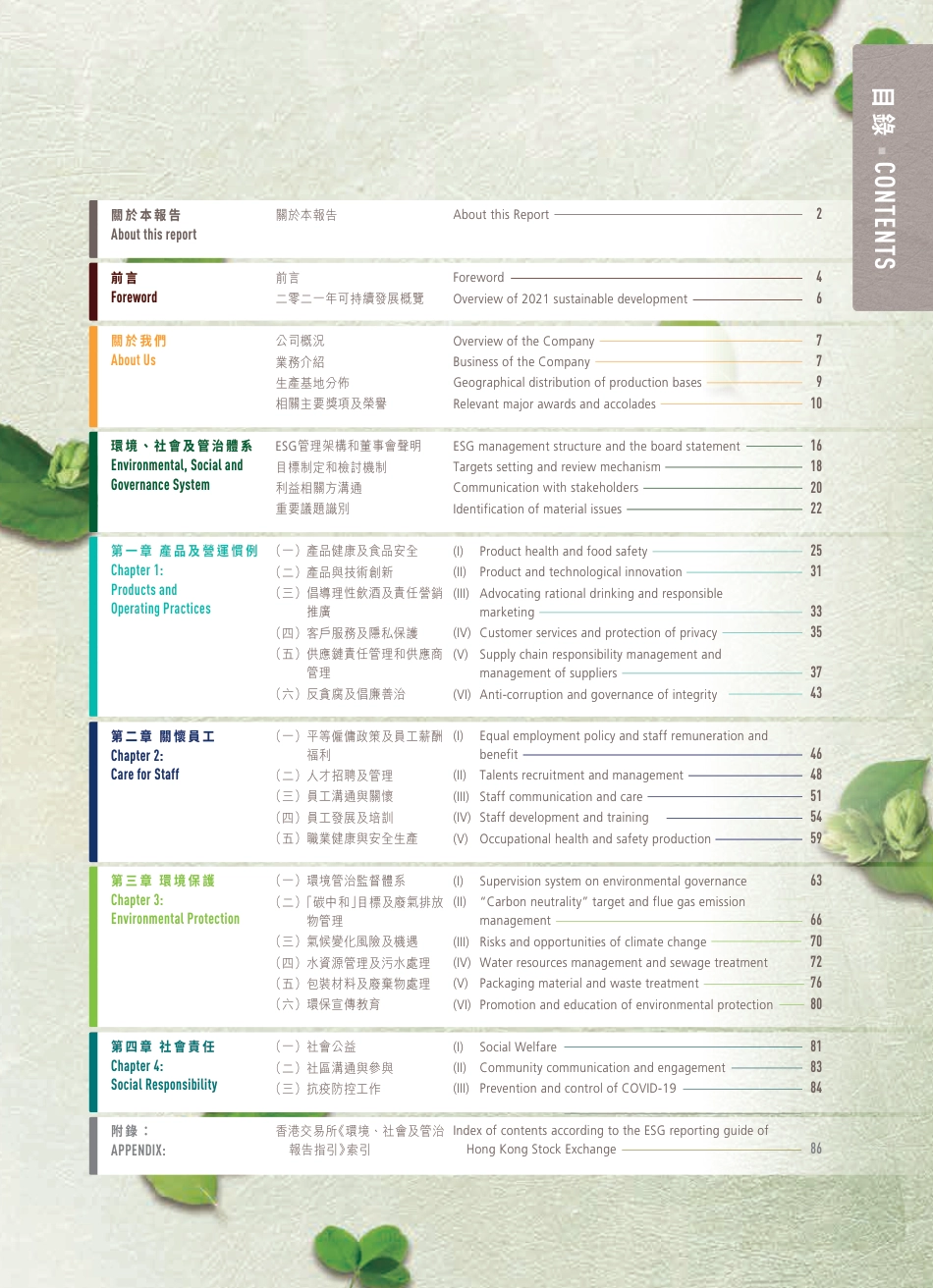

20212021於香港註冊成立的有限公司 Incorporated in Hong Kong with limited liability | 股份代號 Stock Code : 002912021環 境 、 社 會 及 管 治 理 念ENVIRONMENTAL, SOCIAL AND GOVERNANCE PHILOSOPHY本集團堅持「生命健康至上,綠色低碳發展」的理念,追求「零污染、零缺陷、零傷害、零事故」的管理目標,持續完善以價值創造為導向的環境、社會和管治管理體系。以「引領產業發展,釀造美好生活」為使命, 本集團致力於成為消費者信賴、員工自豪、行業領先的國際化綠色釀酒企業。Adhering to the philosophy of “life and health first, green and low carbon development”,the Group pursues the management goal of“zero pollution, zero defects, zero injuries and zero accidents”and continue to improve a value-creating-orientedenvironmental, social and governance management system.With the mission of “leading industrial development, brewing a better life”,the Group strives to become an industrial-leading, international and green brewery enterprisewhich has earned consumers’ trust and is the pride of our staff.設計、印刷及製作:智盛財經媒體有限公司 Design, Printing & Production: GenNex Financial Media Limitedwww.gennexfm.comENVIRONMENTAL, SOCIAL AND GOVERNANCE REPORT 2021 環 境 、 社 會 及 管 治 報 告20212021於香港註冊成立的有限公司 Incorporated in Hong Kong with limited liability | 股份代號 Stock Code : 002912021地址:香港灣仔港灣道26號華潤大廈23樓2301&2310室電話:852-2360-9722 傳真:852-2874-0280網址:www.crbeer.com.hk 電郵:info@crb.cn Address: Room 2301 & 2310, 23/F., China Resources Building, 26 Harbour Road, Wanchai, Hong KongTel: 852-2360-9722 Fax: 852-2874-0280Website: www.crbeer.com.hk Email: info@crb.cn關 於 本 報 告About this report關於本報告About this Report2前 言Foreword前言Foreword4二零二一年可持續發展概覽Overview of 2021 sustainable development6關 於 我 們About Us公司概況Overview of the Company7業務介紹Business of...