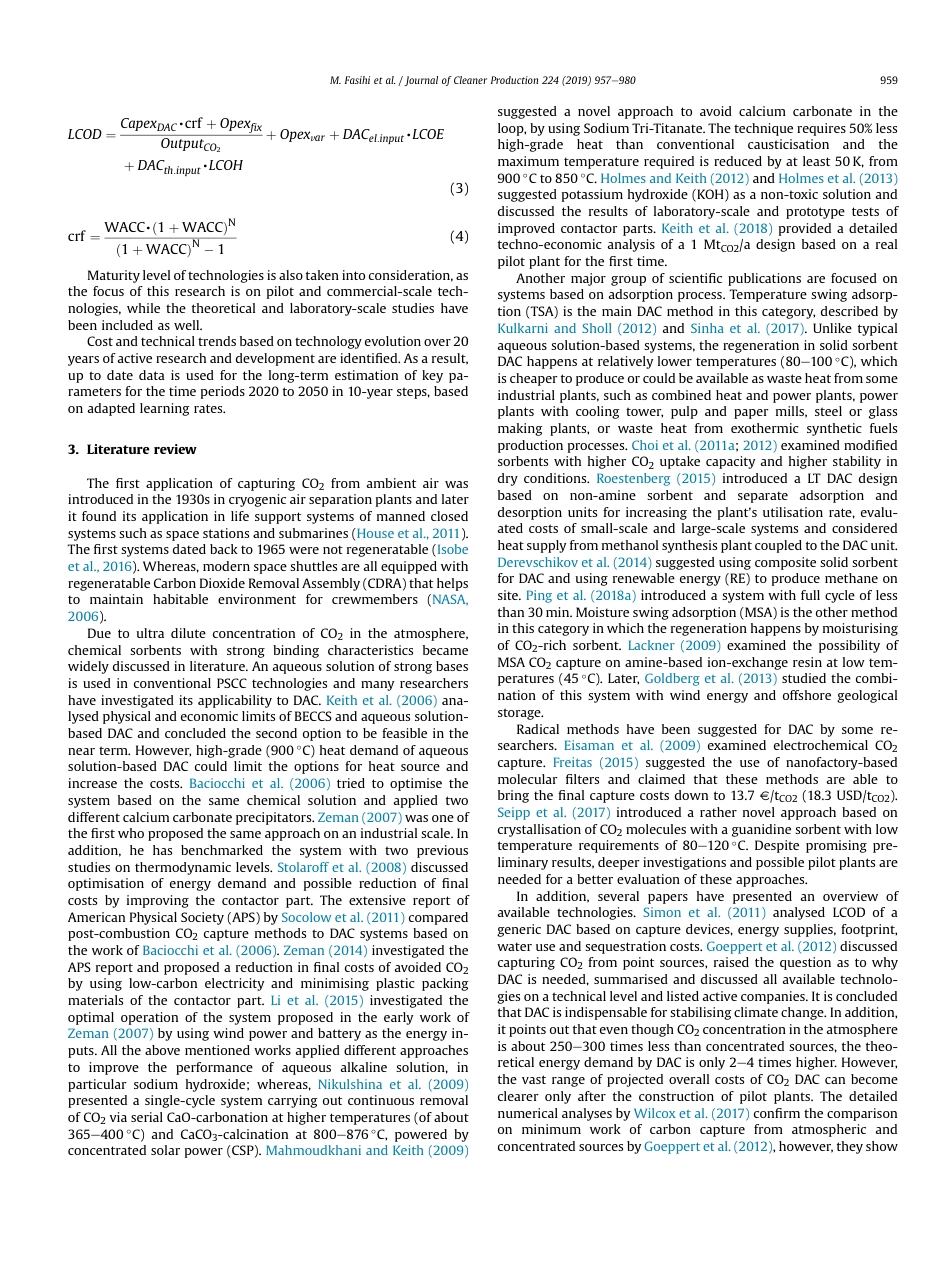

Techno-economic assessment of CO2 direct air capture plantsMahdi Fasihi*, Olga Efimova, Christian BreyerLUT University, Yliopistonkatu 34, 53850, Lappeenranta, Finlanda r t i c l e i n f oArticle history:Received 14 October 2018Received in revised form25 January 2019Accepted 8 March 2019Available online 14 March 2019Keywords:Carbon dioxide (CO2)Direct air capture (DAC)Carbon capture and utilisation (CCU)Negative emission technology (NET)Economicsa b s t r a c tCO2 direct air capture (DAC) has been increasingly discussed as a climate change mitigation option.Despite technical advances in the past decade, there are still misconceptions about DAC's current andlong-term costs as well as energy, water and area demands. This could undermine DAC's anticipated rolein a neutral or negative greenhouse gas emission energy system, and influence policy makers. In thisstudy, a literature review and techno-economic analyses of state-of-the-art DAC technologies are per-formed, wherein, DAC technologies are categorised as high temperature aqueous solutions (HT DAC) andlow temperature solid sorbent (LT DAC) systems, from an energy system perspective. DAC capital ex-penditures, energy demands and costs have been estimated under two scenarios for DAC capacities andfinancial learning rates in the period 2020 to 2050. DAC system costs could be lowered significantly withcommercialisation in the 2020s followed by massive implementation in the 2040s and 2050s, makingthem cost competitive with point source carbon capture and an affordable climate change mitigationsolution. It is concluded that LT DAC systems are favourable due to lower heat supply costs and thepossibility of using waste heat from other systems. CO2 capture costs of LT DAC systems...