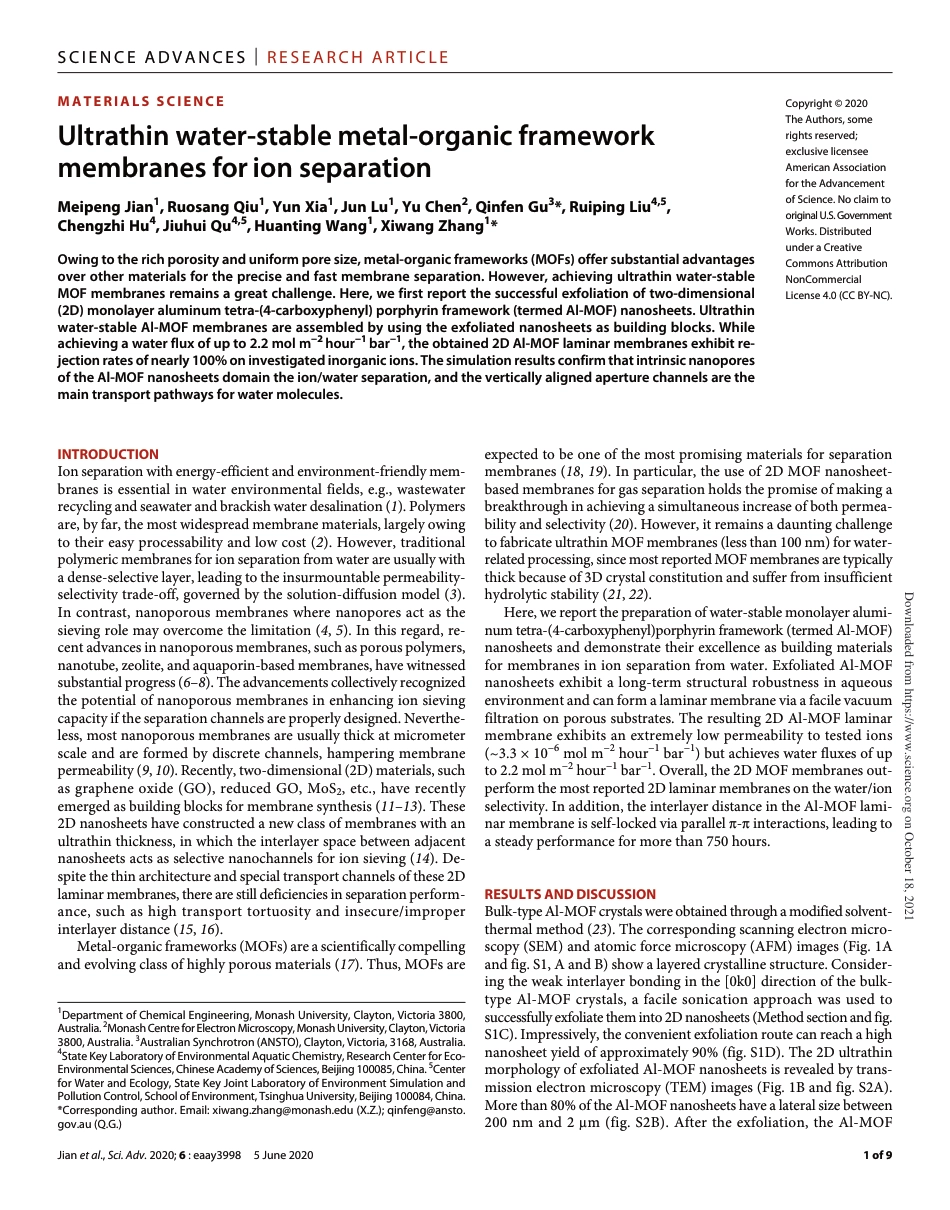

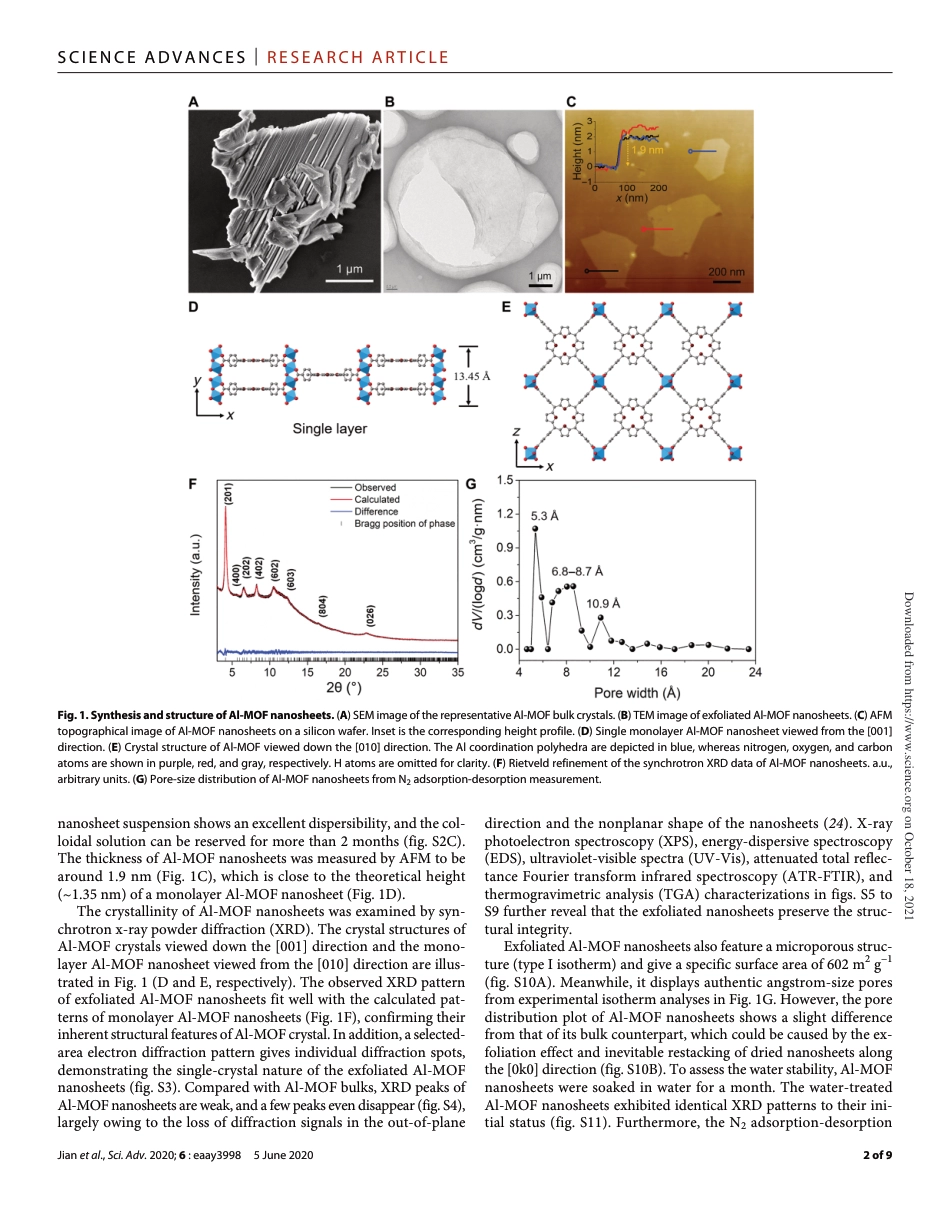

Jian et al., Sci. Adv. 2020; 6 : eaay3998 5 June 2020SCIE N C E A D V A NCES | RESEA R CH A RT ICL E1 of 9M A T E RIALS SCIENC EUltrathin water-stable metal-organic framework membranes for ion separationMeipeng Jian1, Ruosang Qiu1, Yun Xia1, Jun Lu1, Yu Chen2, Qinfen Gu3*, Ruiping Liu4,5, Chengzhi Hu4, Jiuhui Qu4,5, Huanting Wang1, Xiwang Zhang1*Owing to the rich porosity and uniform pore size, metal-organic frameworks (MOFs) offer substantial advantages over other materials for the precise and fast membrane separation. However, achieving ultrathin water-stable MOF membranes remains a great challenge. Here, we first report the successful exfoliation of two-dimensional (2D) monolayer aluminum tetra-(4-carboxyphenyl) porphyrin framework (termed Al-MOF) nanosheets. Ultrathin water-stable Al-MOF membranes are assembled by using the exfoliated nanosheets as building blocks. While achieving a water flux of up to 2.2 mol m−2 hour−1 bar−1, the obtained 2D Al-MOF laminar membranes exhibit re-jection rates of nearly 100% on investigated inorganic ions. The simulation results confirm that intrinsic nanopores of the Al-MOF nanosheets domain the ion/water separation, and the vertically aligned aperture channels are the main transport pathways for water molecules.INTRODUCTIONIon separation with energy-efficient and environment-friendly mem-branes is essential in water environmental fields, e.g., wastewater recycling and seawater and brackish water desalination (1). Polymers are, by far, the most widespread membrane materials, largely owing to their easy processability and low cost (2). However, traditional polymeric membranes for ion separation from water are usually with a dense-selective layer, leading to the insurmountable perm...