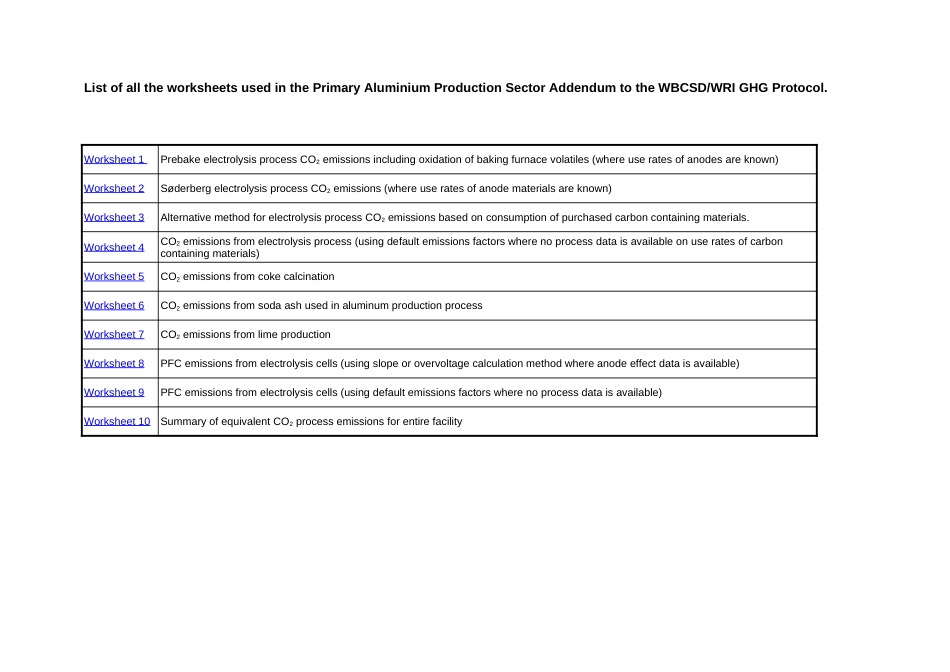

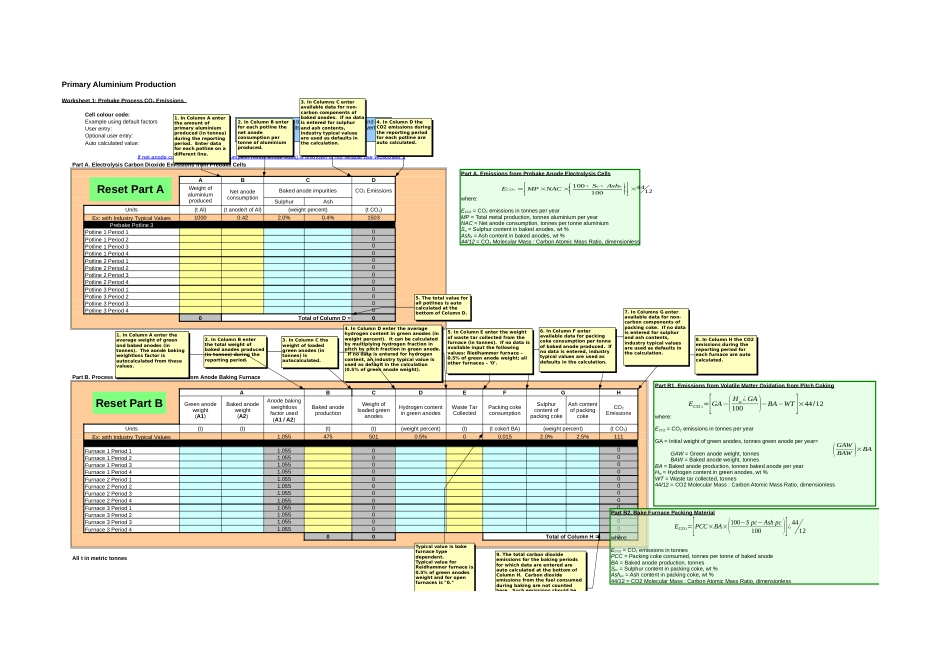

CalculatingDirectGHGemissionsfromPrimaryAluminumProductionCalculationworksheetsPurposeanddomainofthistoolAcknowledgementsTheguidelinesaretheresultofupdateandrevisionbyJerryMarks,InternationalAluminiumInstitute,andFraserThompson(Alcan)oforiginalworkpreparedbyMarieMarache,PricewaterhouseCoopers,withmajorcontributionsfromtheInternationalAluminiumInstitute(London),KennethMartchek(Alcoa),HalvorKvande(NorskHydro),StevePomper(Alcan),andJoeCasolaandVikramBakshifromICFConsulting.referstotheaddedlabelsandnottotheinherentExcelcolumndesignations.ResetingWorksheetsToavoiderasingformulasfromworksheetswhenresettingtobeginanewcalculationseriesclicktheResetbuttonontheworksheet.Pleasecitetheoriginalreferencewheneverusingthistool.Whiletheworksheetsarelargelyselfexplanatoryforquestionsorsuggestionsonitscontents,pleasecontactghgquestions@wri.orgPleasevisittheGHGProtocolInitiativeatwww.ghgprotocol.orgforotherGHGcalculationtools.ThistoolintendstofacilitatethecalculationofdirectGHGemissionsfromprimaryaluminumproduction(CO2fromanodeoxidationandperfluorocarbonfromthe“anodeeffect”phenomena),aswellasCO2emissionsfromrelatedprocesses(cokecalcination,limeproduction)Thisdocumentistobeusedinconjunctionwithadditionaldocuments:1)‘TheAluminiumSectorAddendumtotheWBCSD/WRIGreenhouseGasProtocol,notablyitsAppendixB"ExcelSpreadsheetToolandGuidanceforCalculatingTotalCarbonDioxideEquivalentEmissionsfromPrimaryAluminiumProduction"2)‘WRI/WBCSD(2004),TheGreenhouseGasProtocol–ACorporateAccountingandReportingStandard(RevisedEdition):http://www.ghgprotocol.org/standard/GHGProtocolCorporateStandard_RevisedEdition.pdf3)'WRI/WBCSD(2015),CalculationToolforDirectEmissionsfromStationaryCombustionVersion2.0:http://www.ghgprotocol.org/templates/GHG5/layout.asp?type=p&MenuId=OTAx4)'WRI/WBCSD(2015),CalculationToolforIndirectCO2emissionsfromtheconsumptionofpurchasedelectricity,heat,and/orsteam:http://www.ghgprotocol.org/templates/GHG5/layout.asp?type=p&MenuId=OTAxWarning:TheusershouldnotethattheletteringofcolumnsasdescribedintheguidancedocumentListofalltheworksheetsusedinthePrimaryAluminiumProductionSectorAddendumtotheWBCSD/WRIGHGProtocol.PFCemissionsfromelectrolysiscells(usingslopeorovervoltagecalculationmethodwhereanodeeffectdataisavailable)PFCemissionsfromelectrolysiscells(usingdefaultemissionsfactorswherenoprocessdataisavailable)Worksheet1PrebakeelectrolysisprocessCO2emissionsincludingoxidationofbakingfurnacevolatiles(whereuseratesofanodesareknown)Worksheet2SøderbergelectrolysisprocessCO2emissions(whereuseratesofanodematerialsareknown)Worksheet3AlternativemethodforelectrolysisprocessCO2emissionsbasedonconsumptionofpurchasedcarboncontainingmaterials.Worksheet4CO2emissionsfromelectrolysisprocess(usingdefaultemissionsfactorswherenoprocessdataisavailableonuseratesofcarboncontainingmaterials)Worksheet5CO2emissionsfromcokecalcinationWorksheet6CO2emissionsfromsodaashusedinaluminumproductionprocessWorksheet7CO2emissionsfromlimeproductionWorksheet8Worksheet9Worksheet10SummaryofequivalentCO2processemissionsforentirefacilityPrimaryAluminiumProductionCellcolourcode:ExampleusingdefaultfactorsUserentry:Optionaluserentry:Autocalculatedvalue:PartA.ElectrolysisCarbonDioxideEmissionsfromPrebakeCellsABCDBakedanodeimpuritiesSulphurAshUnits(tAl)(tanode/tofAl)(weightpercent)Ex:withIndustryTypicalValues10000.422.0%0.4%1503PrebakePotline3Potl...

VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP