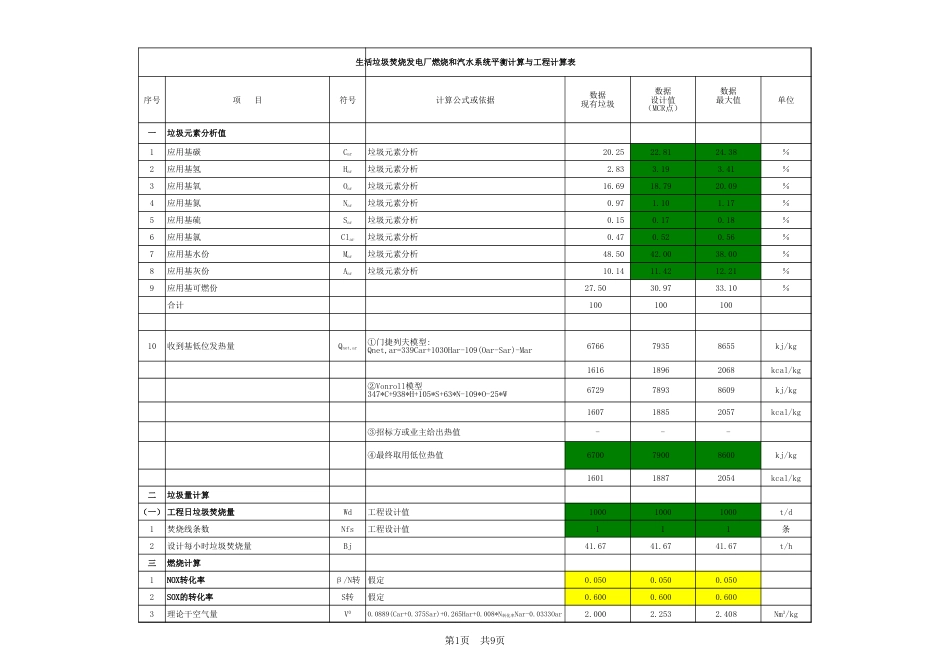

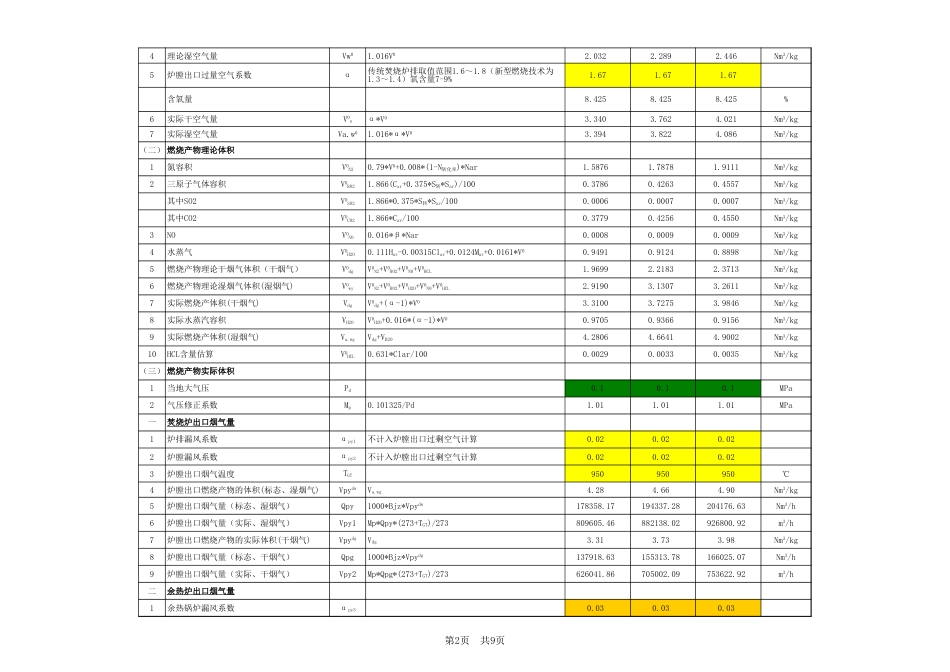

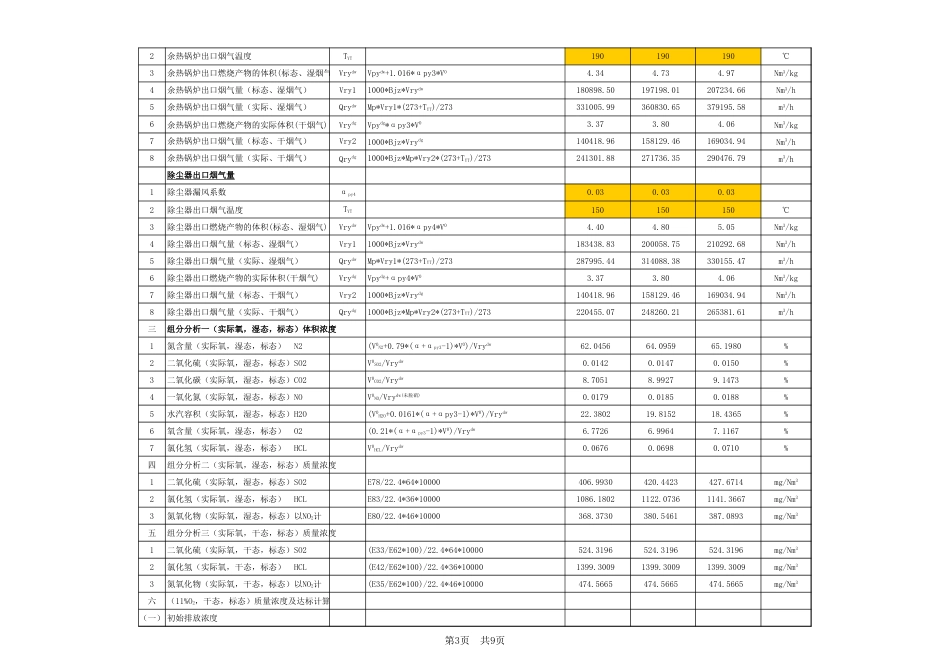

第1页共9页生活垃圾焚烧发电厂燃烧和汽水系统平衡计算与工程计算表序号项目符号计算公式或依据单位一垃圾元素分析值1应用基碳垃圾元素分析20.2522.8124.38%2应用基氢垃圾元素分析2.833.193.41%3应用基氧垃圾元素分析16.6918.7920.09%4应用基氮垃圾元素分析0.971.101.17%5应用基硫垃圾元素分析0.150.170.18%6应用基氯垃圾元素分析0.470.520.56%7应用基水份垃圾元素分析48.5042.0038.00%8应用基灰份垃圾元素分析10.1411.4212.21%9应用基可燃份27.5030.9733.10%合计10010010010收到基低位发热量676679358655kj/kg161618962068kcal/kg672978938609kj/kg160718852057kcal/kg③招标方或业主给出热值---④最终取用低位热值670079008600kj/kg160118872054kcal/kg二垃圾量计算(一)工程日垃圾焚烧量Wd工程设计值100010001000t/d1焚烧线条数Nfs工程设计值111条2设计每小时垃圾焚烧量Bj41.6741.6741.67t/h三燃烧计算1假定0.0500.0500.0502假定0.6000.6000.6003理论干空气量2.0002.2532.408数据现有垃圾数据设计值(MCR点)数据最大值CarHarOarNarSarClarMarAarQnet,ar①门捷列夫模型:Qnet,ar=339Car+1030Har-109(Oar-Sar)-Mar②Vonroll模型347*C+938*H+105*S+63*N-109*O-25*WNOX转化率β/N转SOX的转化率S转V00.0889(Car+0.375Sar)+0.265Har+0.008*N转化率Nar-0.0333OarNm3/kg第2页共9页4理论湿空气量2.0322.2892.4465炉膛出口过量空气系数α1.671.671.67含氧量8.4258.4258.425%6实际干空气量3.3403.7624.0217实际湿空气量3.3943.8224.086(二)燃烧产物理论体积1氮容积1.58761.78781.91112三原子气体容积0.37860.42630.45570.00060.00070.00070.37790.42560.45503NO0.016*β*Nar0.00080.00090.00094水蒸气0.94910.91240.88985燃烧产物理论干烟气体积(干烟气)1.96992.21832.371362.91903.13073.261173.31003.72753.98468实际水蒸汽容积0.97050.93660.915694.28064.66414.9002100.631*Clar/1000.00290.00330.0035(三)燃烧产物实际体积1当地大气压0.10.10.1MPa2气压修正系数0.101325/Pd1.011.011.01MPa一焚烧炉出口烟气量1炉排漏风系数不计入炉膛出口过剩空气计算0.020.020.022炉膛漏风系数不计入炉膛出口过剩空气计算0.020.020.023炉膛出口烟气温度950950950℃44.284.664.905炉膛出口烟气量(标态、湿烟气)Qpy178358.17194337.28204176.636炉膛出口烟气量(实际、湿烟气)Vpy1809605.46882138.02926800.9273.313.733.988炉膛出口烟气量(标态、干烟气)Qpg137918.63155313.78166025.079炉膛出口烟气量(实际、干烟气)Vpy2626041.86705002.09753622.92二余热炉出口烟气量1余热锅炉漏风系数0.030.030.03Vw01.016V0Nm3/kg传统焚烧炉排取值范围1.6~1.8(新型燃烧技术为1.3~1.4)氧含量7-9%V0aα*V0Nm3/kgVa.w01.016*α*V0Nm3/kgV0N20.79*V0+0.008*(1-N转化率)*NarNm3/kgV0RO21.866(Car+0.375*S转*Sar)/100Nm3/kg其中SO2V0SO21.866*0.375*S转*Sar/100Nm3/kg其中CO2V0CO21.866*Car/100Nm3/kgV0NONm3/kgV0H2O0.111Har-0.00315Clar+0.0124Mar+0.0161*V0Nm3/kgV0dgV0N2+V0RO2+V0NO+V0HCLNm3/kg燃烧产物理论湿烟气体积(湿烟气)V0wyV0N2+V0RO2+V0H2O+V0NO+V0HCLNm3/kg实际燃烧产体积(干烟气)VdgV0dg+(α-1)*V0Nm3/kgVH2OV0H2O+0.016*(α-1)*V0Nm3/kg实际燃烧产体积(湿烟气)Va.wgVdg+VH2ONm3/kgHCL含量估算V0HCLNm3/kgPdMpαpy1αpy2TGT炉膛出口燃烧产物的体积(标态、湿烟气)VpydwVa.wgNm3/kg1000*Bjz*VpydwNm3/hMp*Qpy*(273+TGT)/273m3/h炉膛出口燃烧产物的实际体积(干烟气)VpydgVdgNm3/kg1000*Bjz*VpydgNm3/hMp*Qpg*(273+TGT)/273m3/hαpy3第3页共9页2余热锅炉出口烟气温度190190190℃34.344.734.974余热锅炉出口烟气量(标态、湿烟气)Vry1180898.50197198.01207234.665余热锅炉出口烟气量(实际、湿烟气)331005.99360830.65379195.5863.373.804.067余热锅炉出口烟气量(标态、干烟气)Vry2140418.96158129.46169034.948余热锅炉出口烟气量(实际、干烟气)241301.88271736.35290476.79除尘器出口烟气量1除尘器漏风系数0.030.030.032除尘器出口烟气温度150150150℃34.404.805.054除尘...

VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP VIP

VIP