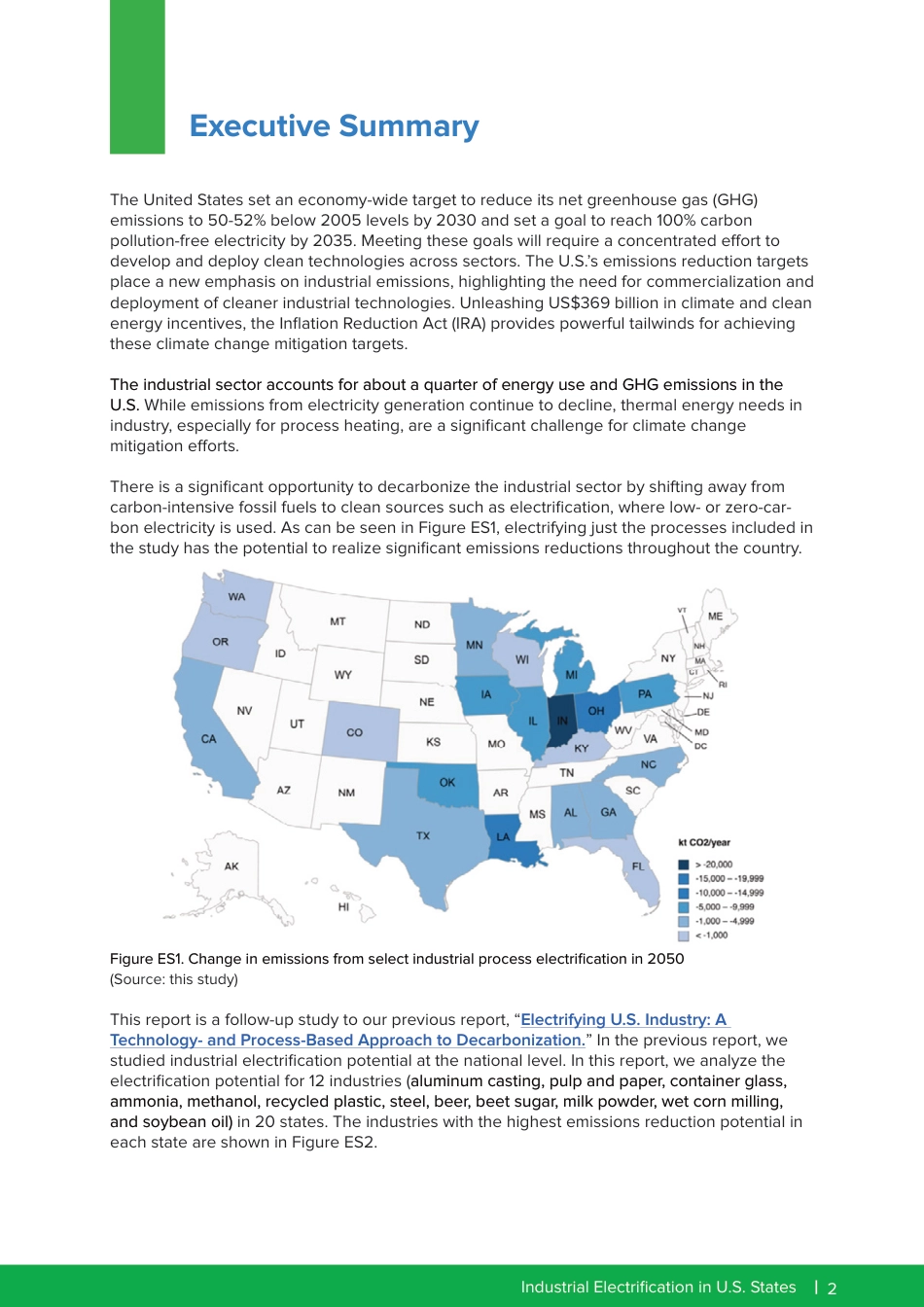

Ali Hasanbeigi, Ph.D. - Global Efficiency IntelligenceLynn A. Kirshbaum and Blaine Collison - David Gardiner and AssociatesIndustrial Electrification in U.S. StatesAn industrial subsector and state-level techno-economic analysis February 2023 1Industrial Electrification in U.S. StatesForeword by the authorsThis report is a follow-up study to our previous report, “Electrifying U.S. Industry: A Technology- and Process-Based Approach to Decarbonization.” In the previous report, we studied the electrification potential for U.S. industry across 12 sub-sectors at the national level. In this report, we analyze the electrification potential for the same 12 sub-sectors, but at the state level, focusing on 20 states. The differences in industries, energy prices, and electricity grid emissions factors across different states are considered in this study to determine the electrification potential. AcknowledgementsThis report was made possible with support from the ClimateWorks Foundation. The authors would like to thank Rebecca Dell, Dan Fahey, and Lauren Marshall of the ClimateWorks Foundation, Claire Dougherty and David Gardiner of David Gardiner and Associates, Jibran Zuberi of Lawrence Berkeley National Laboratory, Ed Rightor of ACEEE, Colin McMillan of the National Renewable Energy Laboratory, Sara Baldwin of Energy Innovation, and John Marano of JM Energy Consulting for their valuable input to this study and/or their insightful comments on earlier versions of this document. DisclaimerGlobal Efficiency Intelligence, LLC and David Gardiner and Associates have provided the information in this publication for informational purposes only. Although great care has been taken to maintain the accuracy of the information collected and pres...